The challenges

In the highly competitive and highly automated automotive sector, Prima Sole Components felt the need to digitally overhaul the entire production

management process in the injection molding area.

The existing systems did not provide real-time visibility into process data, and information collection was fragmented, often managed manually, poorly integrated with the company’s ERP, and difficult to access in a structured way.

The Solution

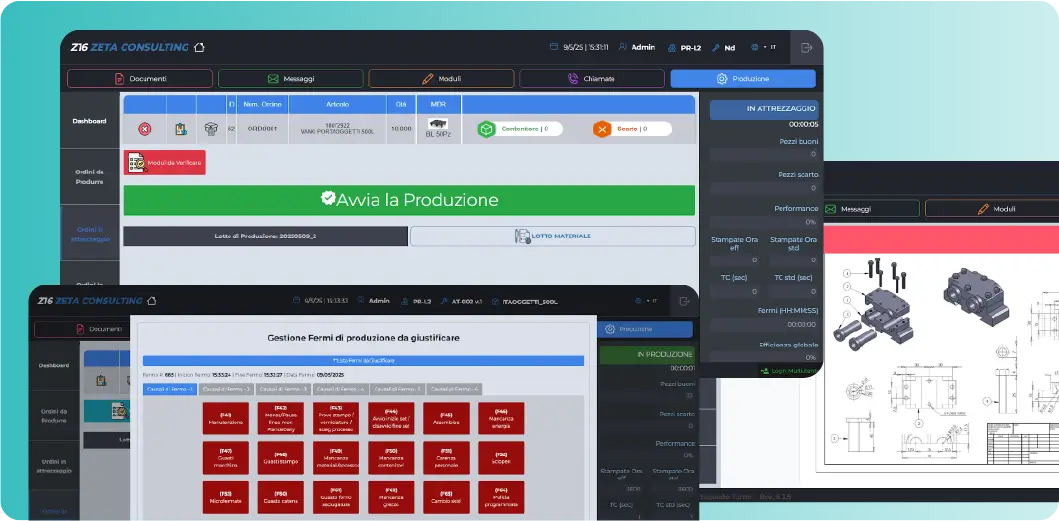

To meet these needs, Prima Sole Components launched a digitalization project in collaboration with Zerynth and Zeta Consulting. The solution was based on the integration of Zerynth’s edge devices with the Zeta MES platform.

The devices, installed in Plug&Play mode on 18 machines, enabled the connection of every machine, allowing real-time collection of production data — such as cycle times and energy consumption — without requiring modifications to the existing equipment.

The Results

The digital transformation of Prima Sole Components’ molding department stemmed from the need to simplify production management, improve data collection, and integrate everything with the existing ERP system.

The collaboration between Zerynth, experts in industrial connectivity and Industrial IoT, and Zeta Consulting, specialists in MES solutions, delivered a scalable, accessible, and ready-to-use system.

Company

Prima Sole Components

Industry

Automotive

Assets

Injection molding machines

Results

18 interconnected machines

Connection and digitalization of both new and legacy equipment

< 6 months implementation time

Complete interconnection and visibility from Edge to ERP

~10% reduction of non-value-a dded activities

Real-time data collection and immediate notifications for more informed