What is Production Insights HMI?

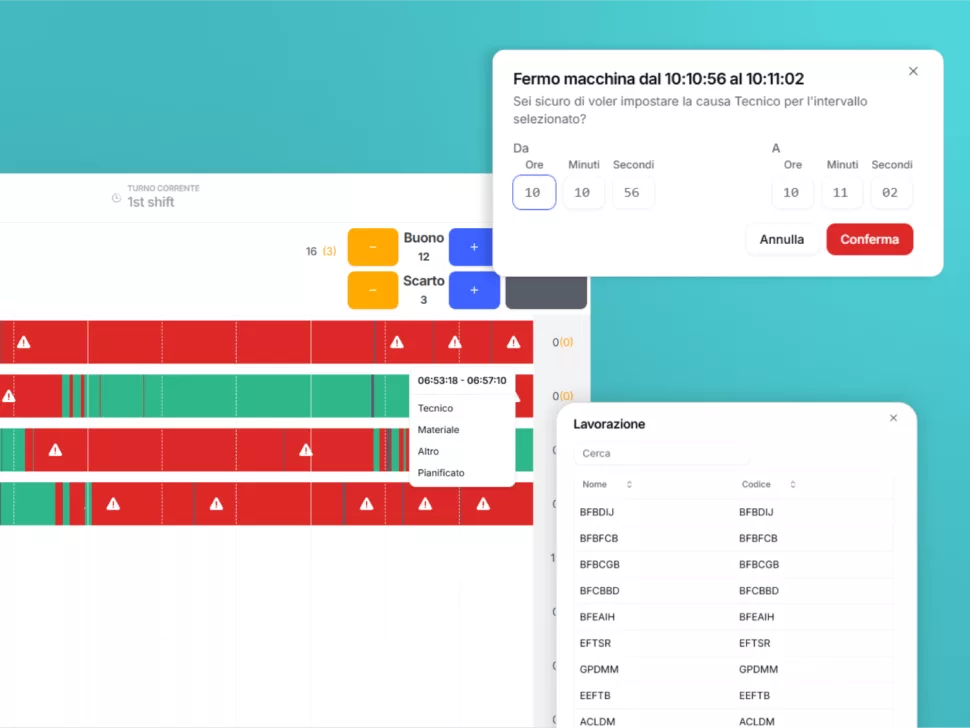

Production Insights HMI is the ideal solution for managing manual stations and production lines without automated machinery. Line operators can easily input data about the tasks performed, creating a traceable workflow fully integrated with Production Insights.

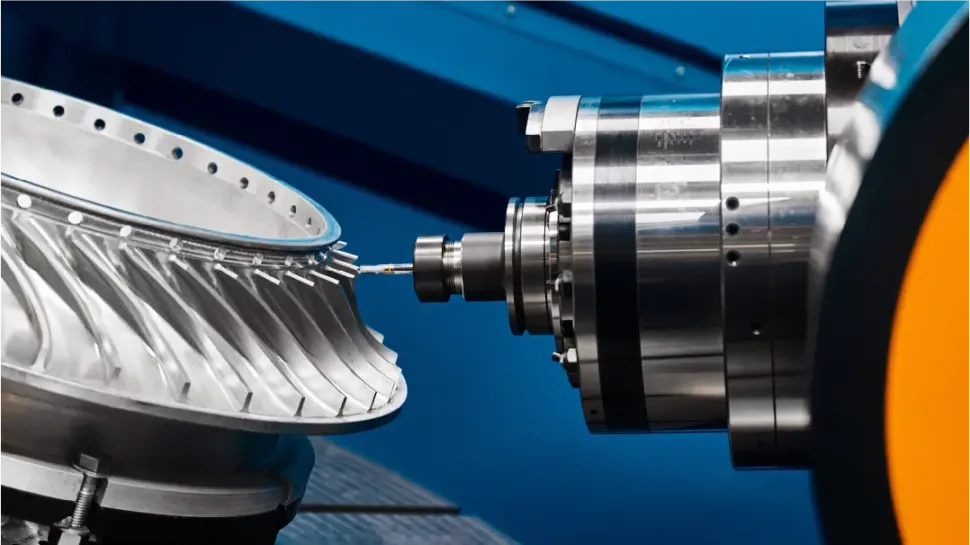

When used alongside digitalized machinery equipped with ZeroBox, Production Insights HMI allows integration of basic information with additional details related to the start and end of individual tasks and the causes of machine downtimes.

Production Insights HMI ensures all activities become part of production analysis, offering precise data and personalized reports for informed decision-making.

What problems does it solve?

Features

What are the benefits?

Transition from manual to digital:

integrate all data into a single platform, covering both manual and mechanical processes. Enable the production Insights app at every level of detail for any type of machinery or workstation.

Accurate productivity analysis:

access detailed and precise data for tracking tasks and analyzing downtime causes.

Versatility:

adaptable to heterogeneous production environments, supporting both manual and automated workflows.

Zerynth natively integrates with any BI, ERP, or MES

Easily connect enterprise third-party tools in a non-invasive way

The Zerynth Industrial IoT & AI Platform can natively interface with any industrial machinery in a simple and non-invasive manner, without interrupting machine operation, and offers quick integration with any BI, ERP, or MES already in your company.

Integration is also available with third-party tools through Rest Open API, Webhook, or certified connectors.