What problems does it solve?

Benefits and features

Efficient and effective remote control of devices and systems

Remote programming of devices and systems, reducing the need for manual work

Seamless integration with management systems for easy operational control

Full compliance with regulations and standards to access tax benefits

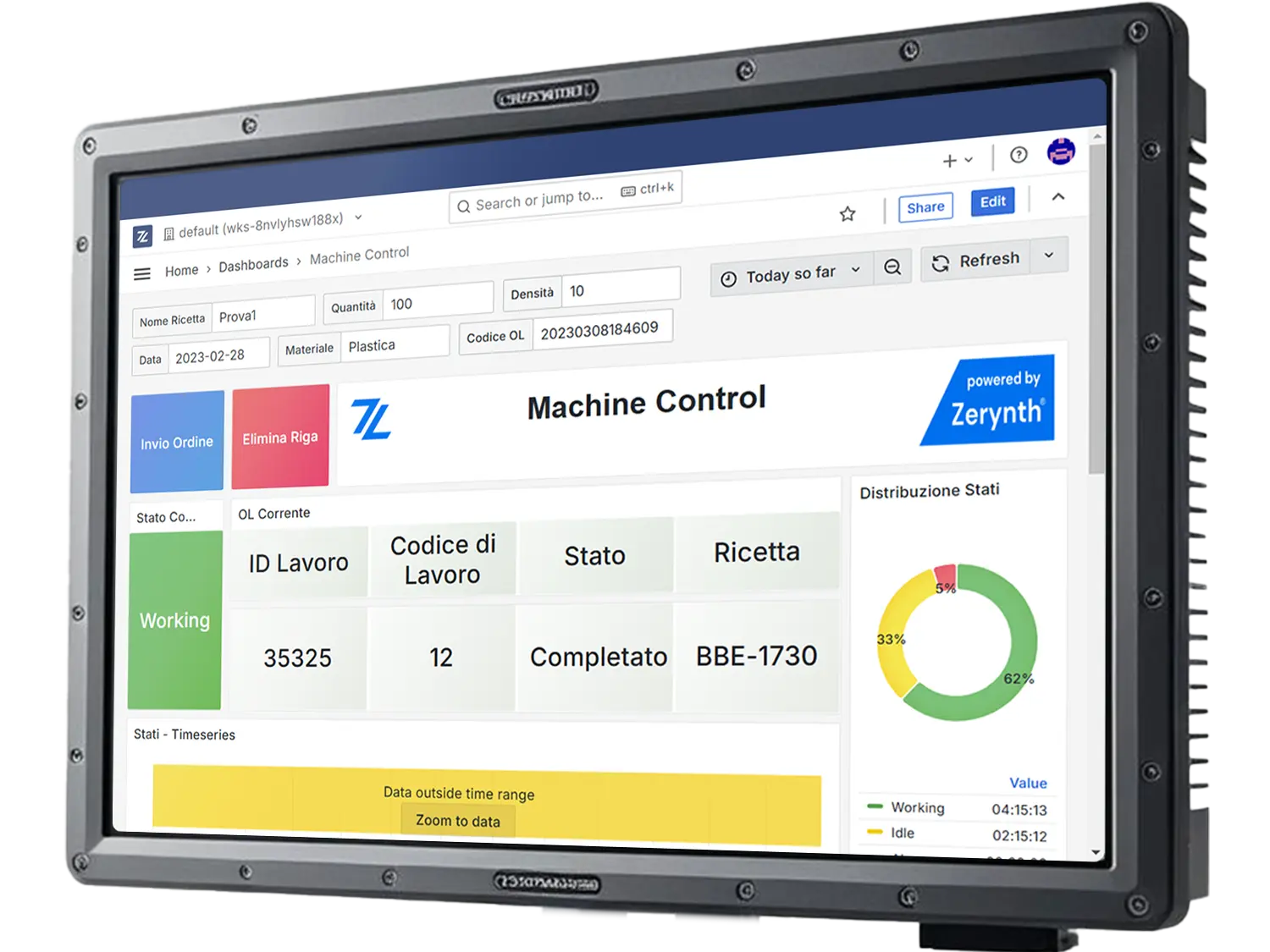

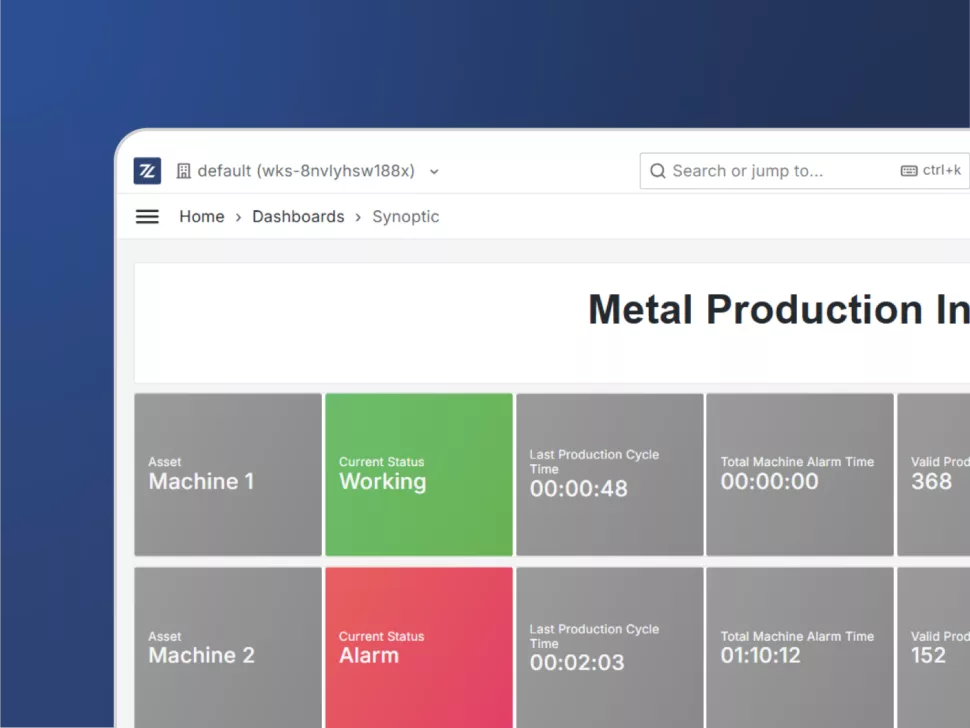

User Interface and Customization

With an intuitive graphical user interface (GUI), sending commands to machines or the PLC has never been easier. Additionally, Zerynth enables the effortless customization of control dashboards to suit specific operational needs.

Zerynth natively integrates with any BI, ERP, or MES

Easily connect enterprise third-party tools in a non-invasive way

The Zerynth Industrial IoT & AI Platform can natively interface with any industrial machinery in a simple and non-invasive manner, without interrupting machine operation, and offers quick integration with any BI, ERP, or MES already in your company.

Integration is also available with third-party tools through Rest Open API, Webhook, or certified connectors.

Case Study

Case Study