Problems we solve in Production Tracking

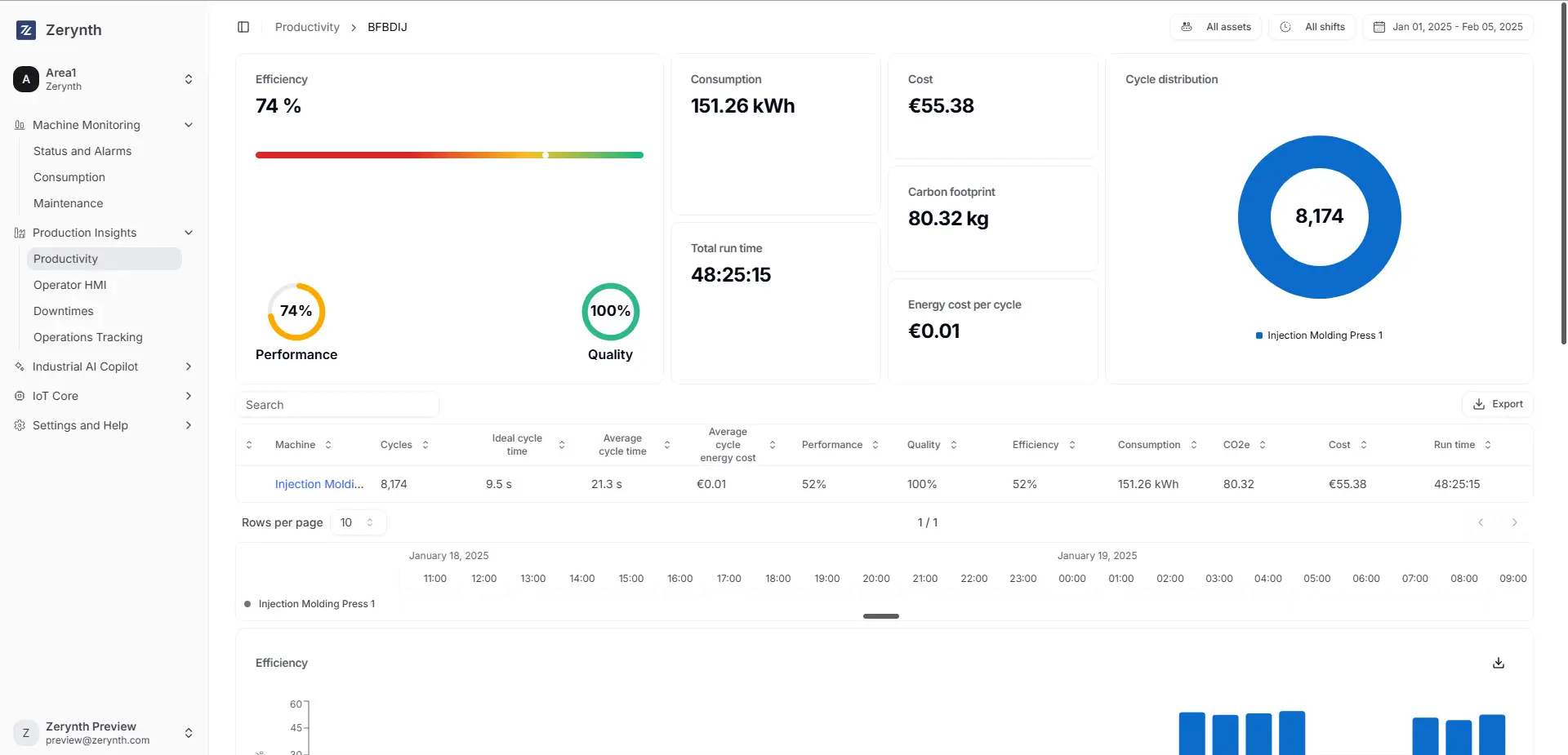

Lack of machine information

Without an effective tracking system, it is challenging to know the operating conditions of machines, which can impact quality and productivity.

Inability to identify inefficiencies and bottlenecks

Companies often struggle to pinpoint specific problems in machine performance or production processes, leading to production halts.

Difficulty linking production data to work orders

Many companies find it hard to analyze data, identify inefficiencies, and understand how to prevent production issues.

Automating ERP/MES factory data

The dispersion of information across various production management systems makes it complicated to collect reliable and timely data in ERP/MES.

Time and Methods: identify the cause of downtime effortlessly

Whether you gave a ZeroBox connected to a machine or an active operator interface, you can immediately identify causes of downtime and inefficiencies.

This makes it easy to base production decisions on real data from your process history, determining when, on which lines, or on which machines to plan production.

Supporting Your Digital Transformation

With Zerynth’s method, we offer advanced technology and a robust network of partners for a successful journey. We provide monitoring, interconnection, and machine visibility, enabling energy monitoring, enhanced process transparency, and integrated order tracking aligned with production.

Why choose Zerynth?

We combine industrial expertise with technological excellence to offer scalable, flexible solutions tailored to your production needs.

With Zerynth, complete production visibility becomes the foundation for more efficient operations. And when you need support? Our experts are always by your side.

Zerynth natively integrates with any BI, ERP, or MES

Easily connect enterprise third-party tools in a non-invasive way

The Zerynth Industrial IoT & AI Platform can natively interface with any industrial machinery in a simple and non-invasive manner, without interrupting machine operation, and offers quick integration with any BI, ERP, or MES already in your company.

Integration is also available with third-party tools through Rest Open API, Webhook, or certified connectors.

Resources

Resources

FAQ