Challenges

For a manufacturing company, production monitoring and planning are key elements for improving efficiency and sustainability, accelerating the transition to Industry 5.0 and sustainable production.

Gi.Metal, a leader in the production of professional equipment for the foodservice industry, turned to Zerynth to digitally transform its production processes. The goals were to automate data collection, improve real-time visibility into production, and ensure more precise control over the entire manufacturing cycle.

Solution

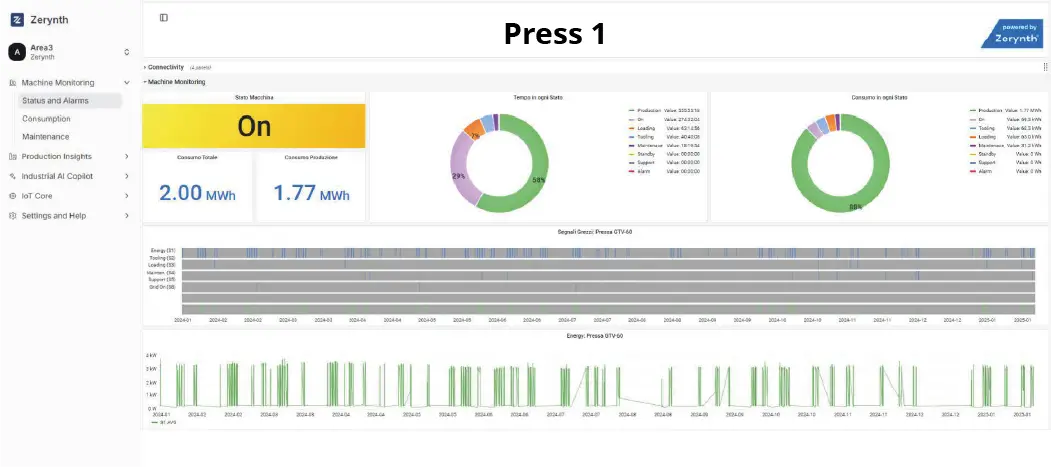

The solution implemented by Zerynth involved installing advanced sensors and Edge devices for the automatic monitoring of machine status (on, off, idle, in production), cycle times, energy consumption, and other key parameters for the company, including production, cycles, and operations. This approach optimized operational efficiency and reduced environmental impact through more conscious resource usage.

Results

The adoption of the Zerynth solution brought numerous advantages to the company, starting with increased productivity. Through digitalization, workflow processes were optimized, significantly reducing downtime and improving overall efficiency. Moreover, real-time visibility into the various stages of production allowed the company to monitor every process precisely, improving planning and resource management.