The Challenges

T.G.R. Srl, a company specializing in mechanical processing such as turning, milling, and grinding for the production of mechanical parts, turned to Zerynth to address challenges related to integrating its existing machinery with management systems.

The solution had to integrate existing machinery with advanced energy monitoring systems, ensuring continuous and uninterrupted data transmission. It was also crucial to monitor all processes in real time to prevent data loss and ensure that every detail was recorded for future analysis.

The Solution

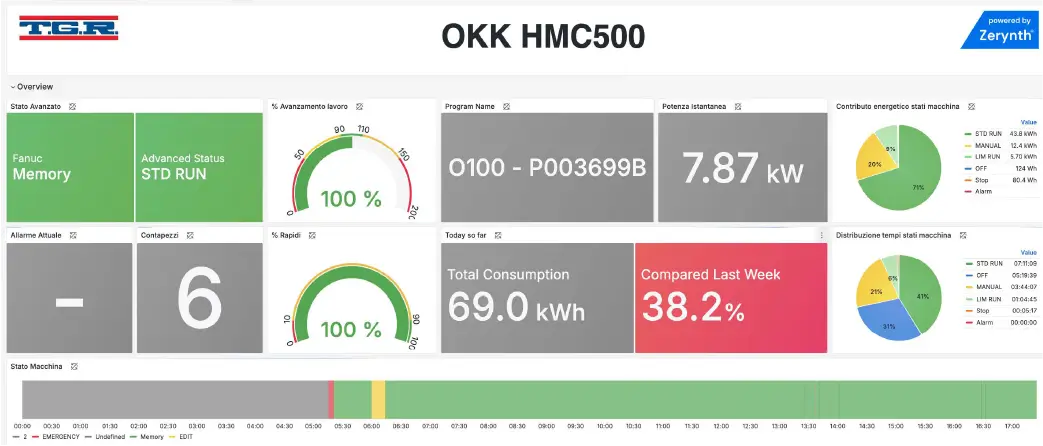

The installation of the Zerynth Platform was the proposed solution for T.G.R. to digitize its machine park and address challenges related to cost reduction and energy consumption, ensuring strategic monitoring of the machinery.

By using clean contacts and sensors equipped with a clamp meter, it was possible to directly measure the energy consumption of the machinery. To ensure even more detailed and responsive management, Zerynth provided the dashboarding tool integrated into the Zerynth platform. This allowed the development of customised dashboards, configured to meet TGR’s specific needs, enabling the immediate and comprehensible display of machinery status, work cycles and energy consumption.

Company

T.G.R. Srl

Industry

Metal manufacturing

Assets

Lathes, Machining Centers, Grinding

Profile

T.G.R. is a company founded in 1977 and specialises in the production of high-quality mechanical parts. The company specialises in machining operations such as turning, milling and grinding for the production of mechanical parts according to drawings and specifications provided by the customer.