The Challenges

With over forty years in the metalworking industry, M.C.A. has consistently emphasized innovation and efficiency. However, rising demand and operational complexity posed new challenges, including the need to improve monitoring and control of the production area, reduce manual operations, and limit on-site interventions.

The clear need was a technological solution providing visibility at all times, decision support, and ease of use for all operators. Thus began the collaboration with Zerynth, a leader in IoT and AI solutions for industry, to initiate an ambitious digital transformation project for the shop floor.

The Solution

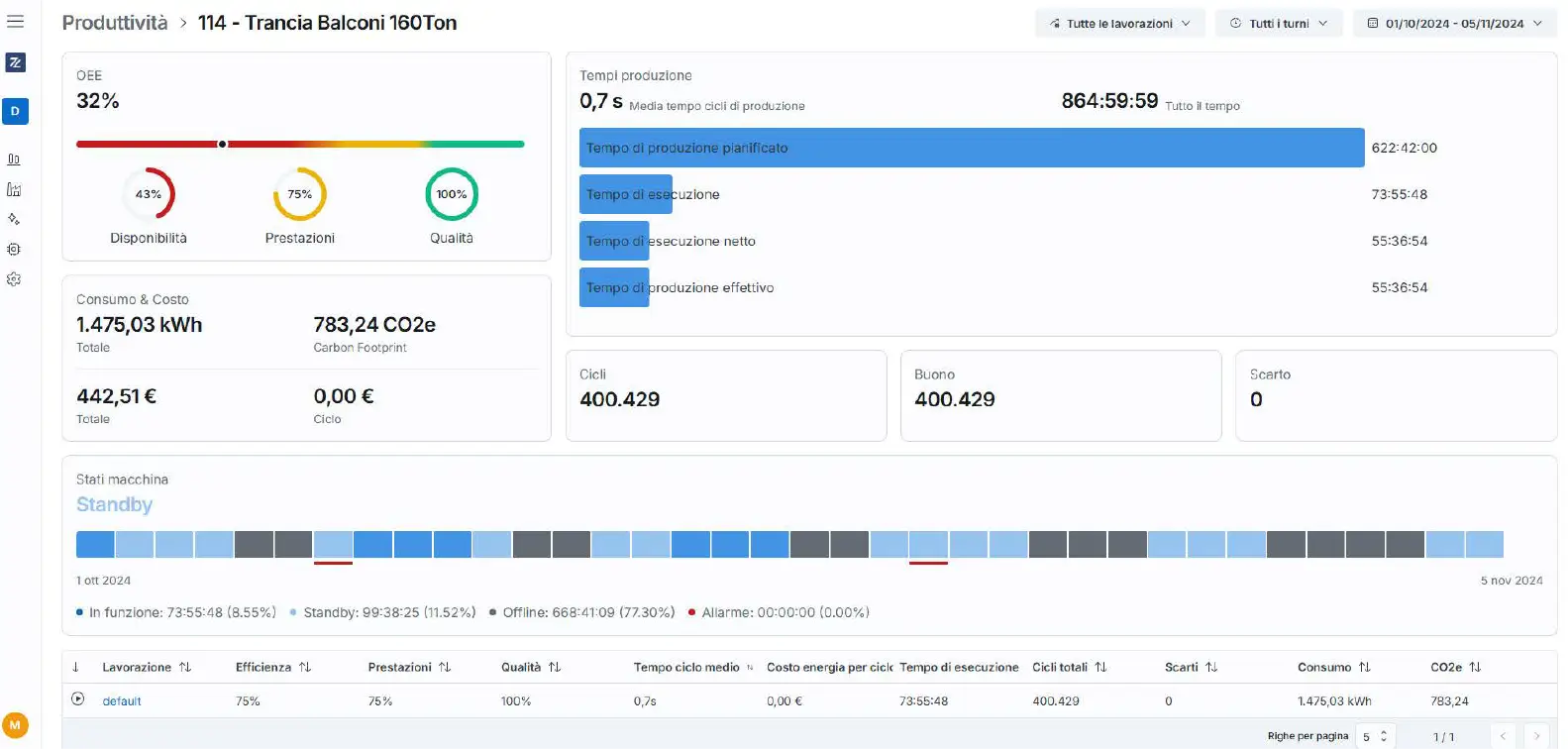

To meet M.C.A.’s needs, Zerynth implemented the Zerynth Industrial IoT & AI Platform in the production plant, connecting seven machines in total: four presses, a laser welder, a riveting machine, and an electropneumatic testing machine. The M.C.A. solution includes Machine Monitoring and Production Insights apps, which enable accurate and intuitive monitoring of machinery, providing the company with a clear, real-time view of production operations.

Results

The entire project—from the initial assessment phase to device installation—was completed in under two months. Thanks to Zero, machine data was immediately accessible to operators and production managers, enabling real-time optimization strategies. The notification system and data access via chat simplify machine management, significantly lowering the learning curve associated with IoT and AI technologies.