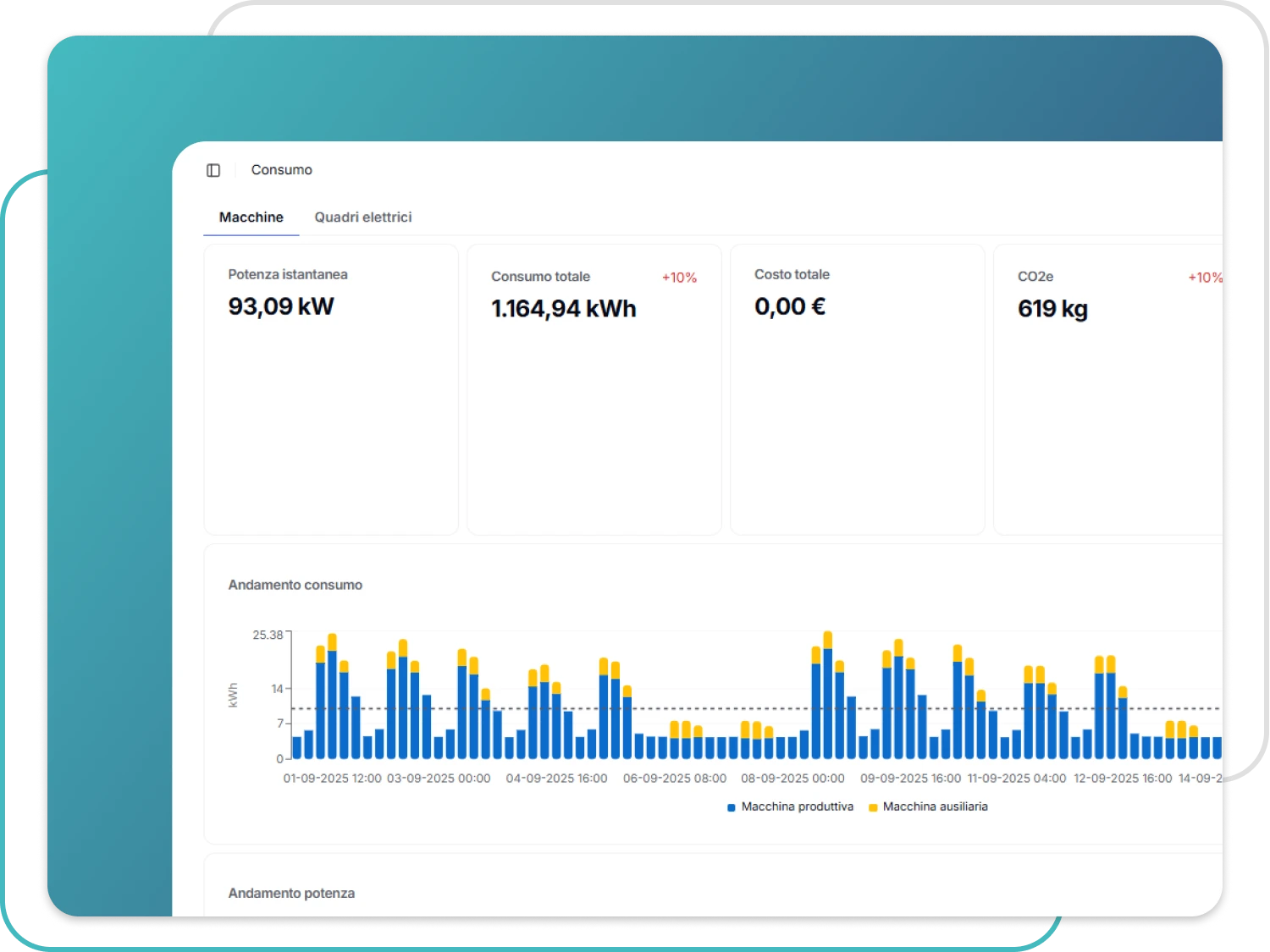

See Where Your Energy Goes

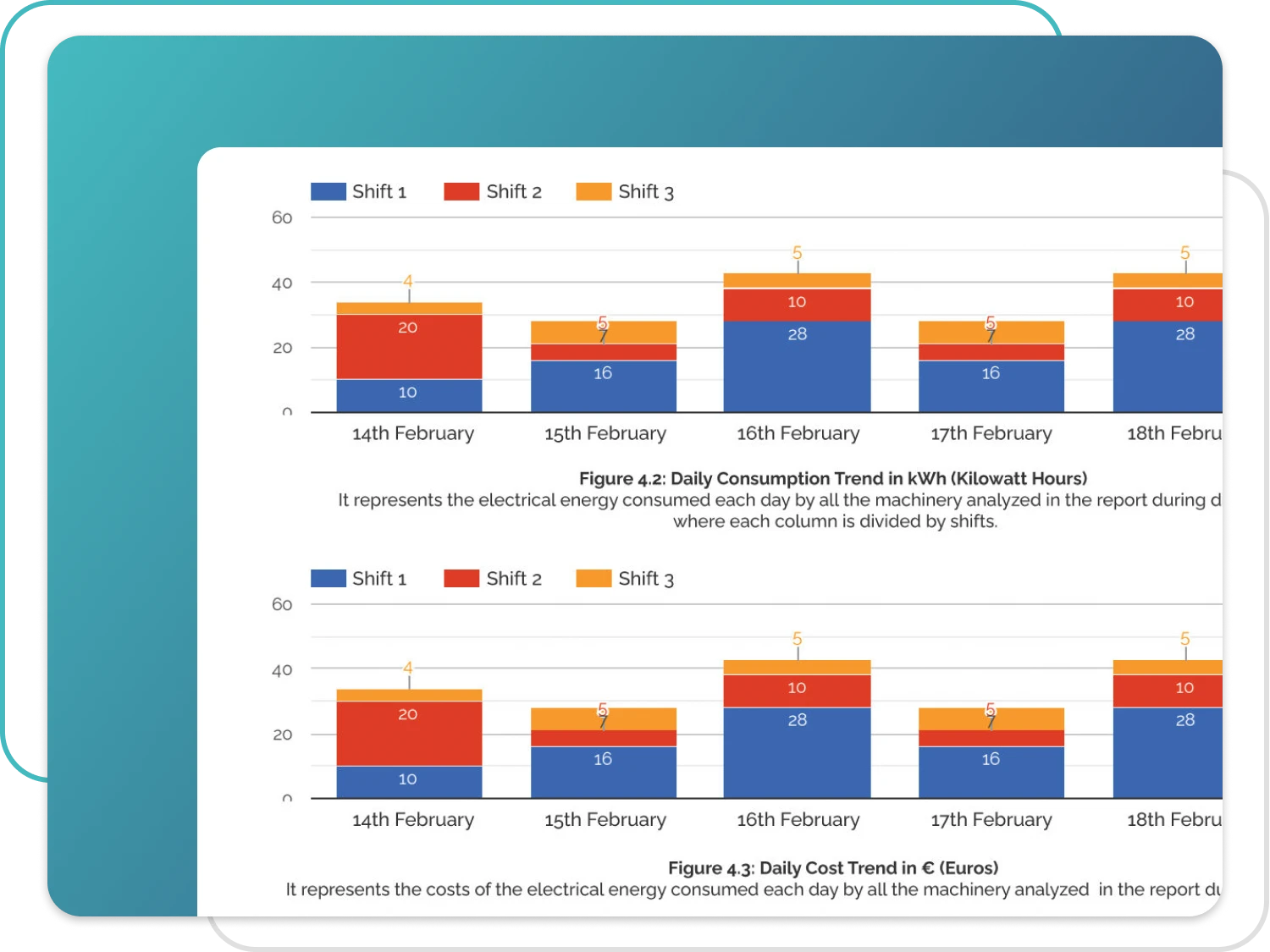

Energy Monitoring is the app that lets you visualize in real time how energy flows through your factory processes. Track consumption, costs, energy distribution, and CO₂e emissions simply, reliably, and with immediate operational impact.

Department Energy Consumption Reduction

Solar Energy Monitoring

Monitor solar energy production, self-consumption, and grid usage to make data-driven decisions for greater energy independence.

Auxiliary Asset Control

Measure energy usage of compressors, HVAC, and other support systems to prevent anomalies and reduce inefficiencies.

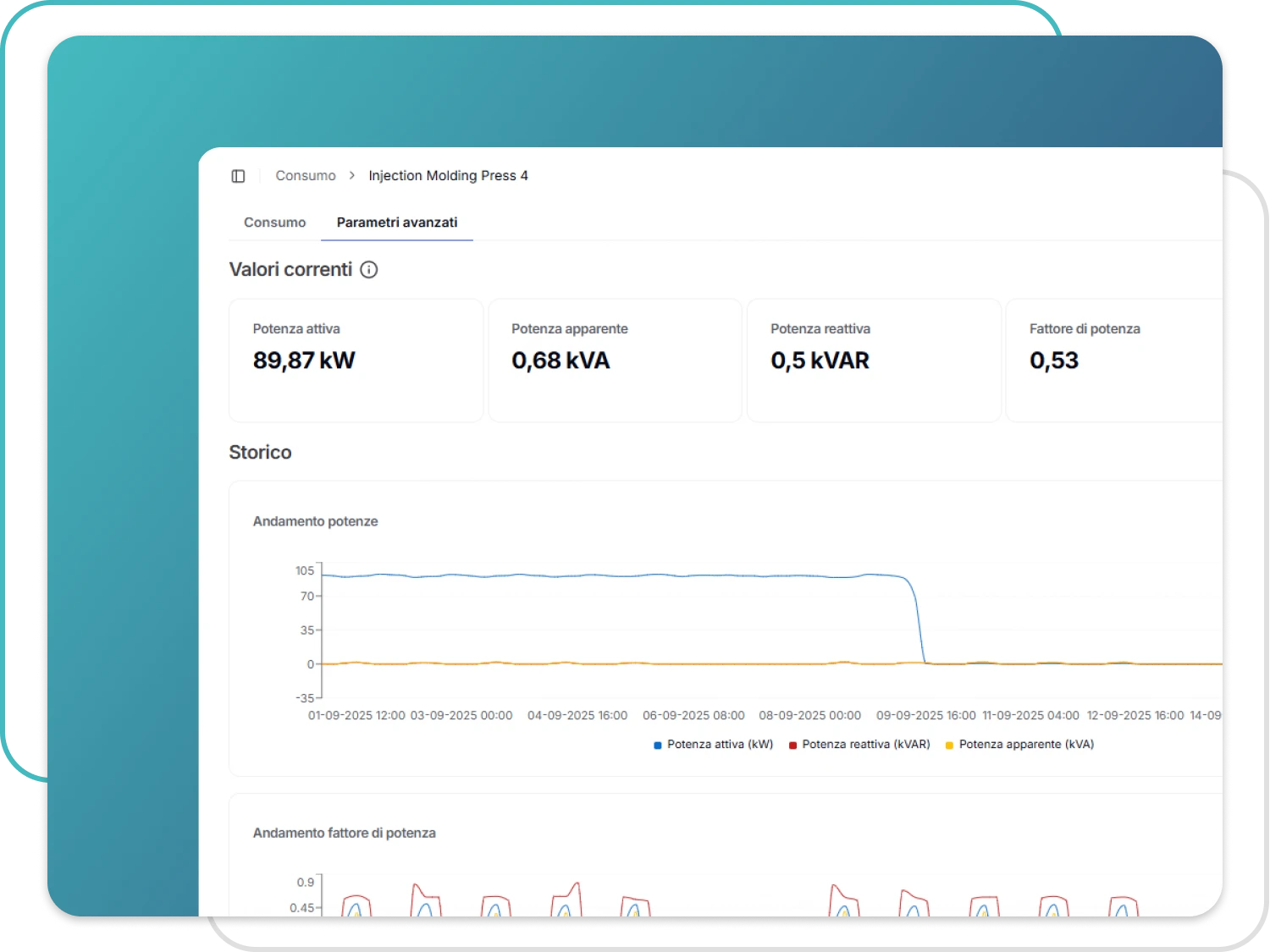

Key Features

Discover why Energy Monitoring is the ideal tool to transform energy data into concrete savings and real-time control.

The First Step Toward a Sustainable Factory

With Energy Monitoring, you start a concrete and incremental journey toward energy efficiency. Data is available immediately and easy to read—even for non-technical users—helping identify improvement opportunities.

Advanced reporting makes it ideal for meeting Industry 5.0 requirements and for EU CO₂ and ESG compliance.

Native Integration with Any BI, ERP, or MES

Seamlessly integrate with third-party management systems without disrupting operations

The Zerynth Industrial IoT & AI Platform connects to any industrial machine simply and non-invasively—without stopping production—and integrates quickly with any existing ERP, MES, or BI system.

Third-party integrations are also available via REST Open API or WebHook.