Zerynth Connector for SAP S/4HANA

Unify your data in a single platform and make smarter strategic decisions.

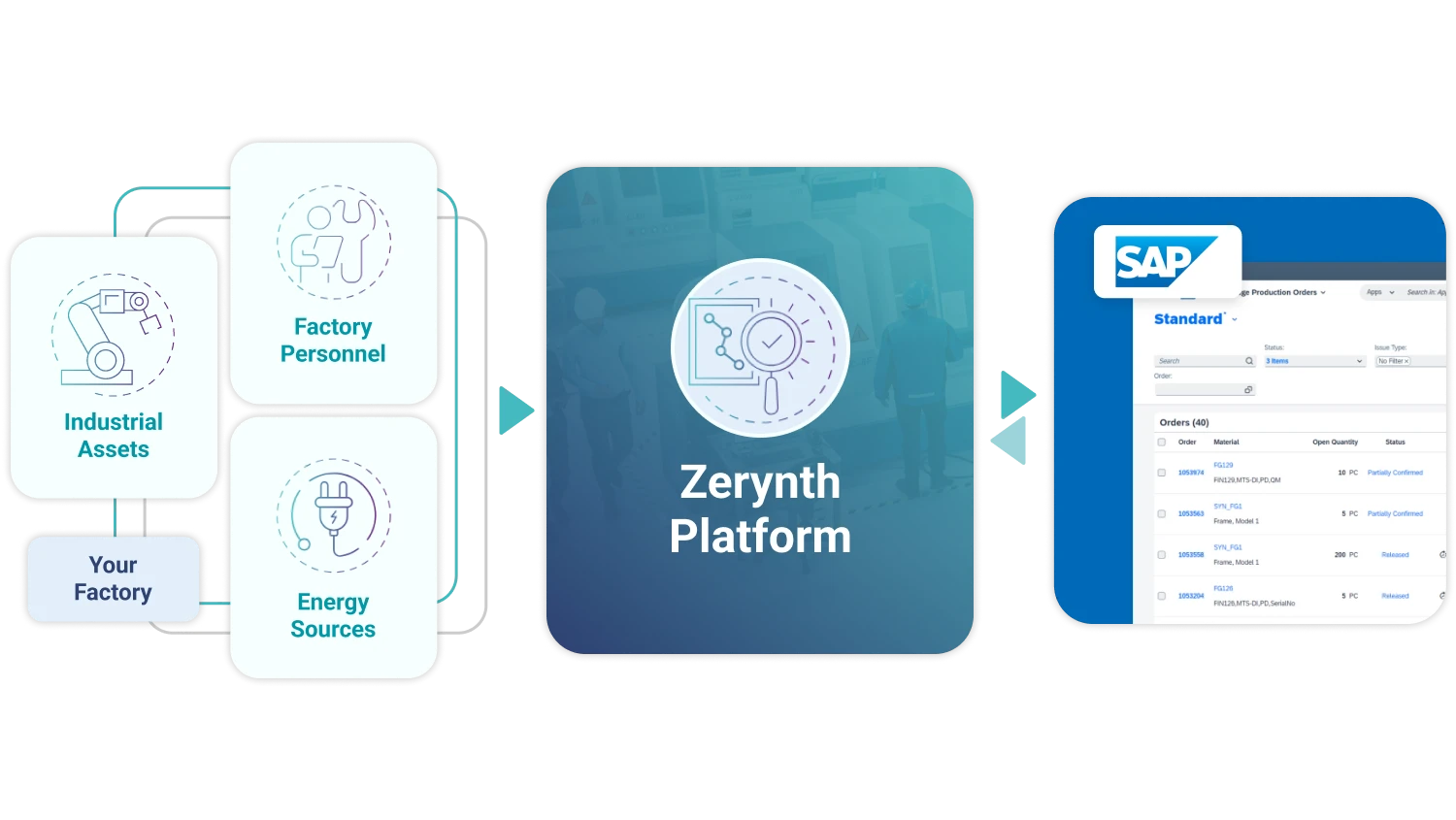

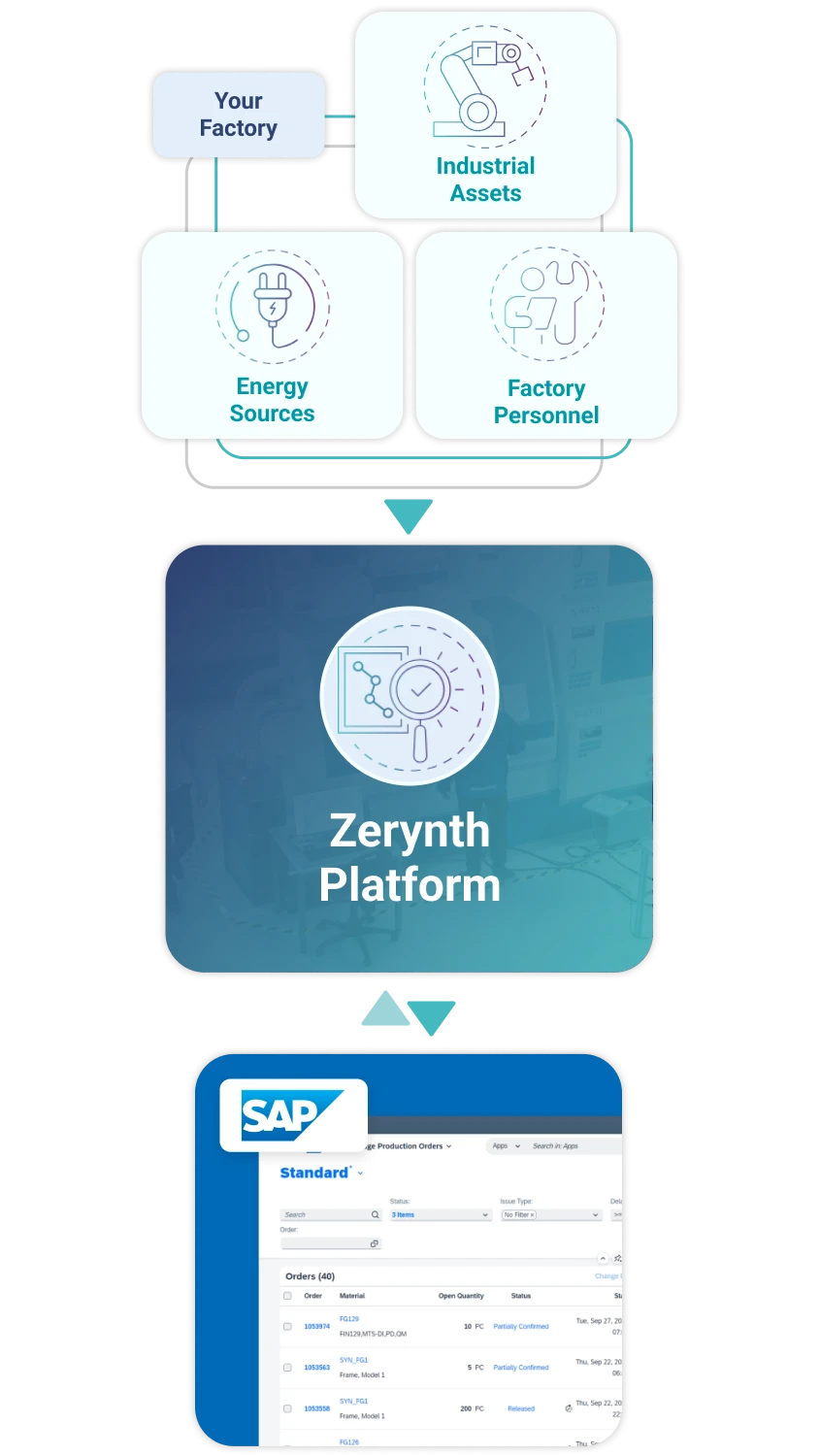

The Zerynth Platform integrates natively with SAP S/4HANA through the SAP Integration Suite, making it easy to acquire and send machine data.

Connect both new and legacy industrial assets without structural changes: with the Zerynth Platform, you can integrate equipment using modern software protocols as well as older machinery through the Zerynth Edge Kit. Fully compatible with both on-premise and SaaS environments.

What You Can Do with the Zerynth x SAP Connector

Key Features

Business Benefits

Direct integration with SAP S/4HANA

via SAP Integration Suite (Cloud Integration)

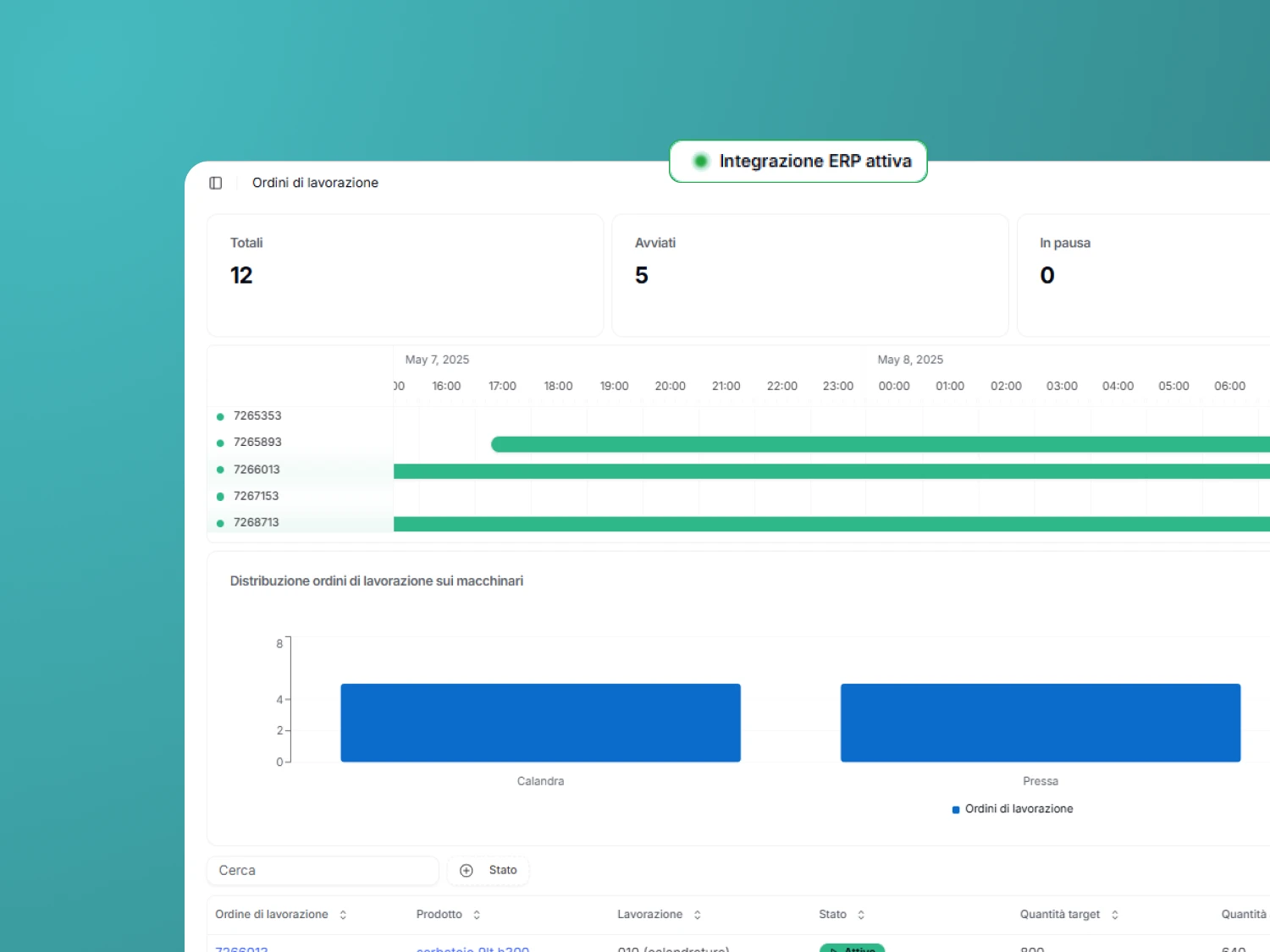

Real-time data extraction

from the Zerynth Platform into SAP

Utilizes standard SAP APIs

to securely confirm and update production orders

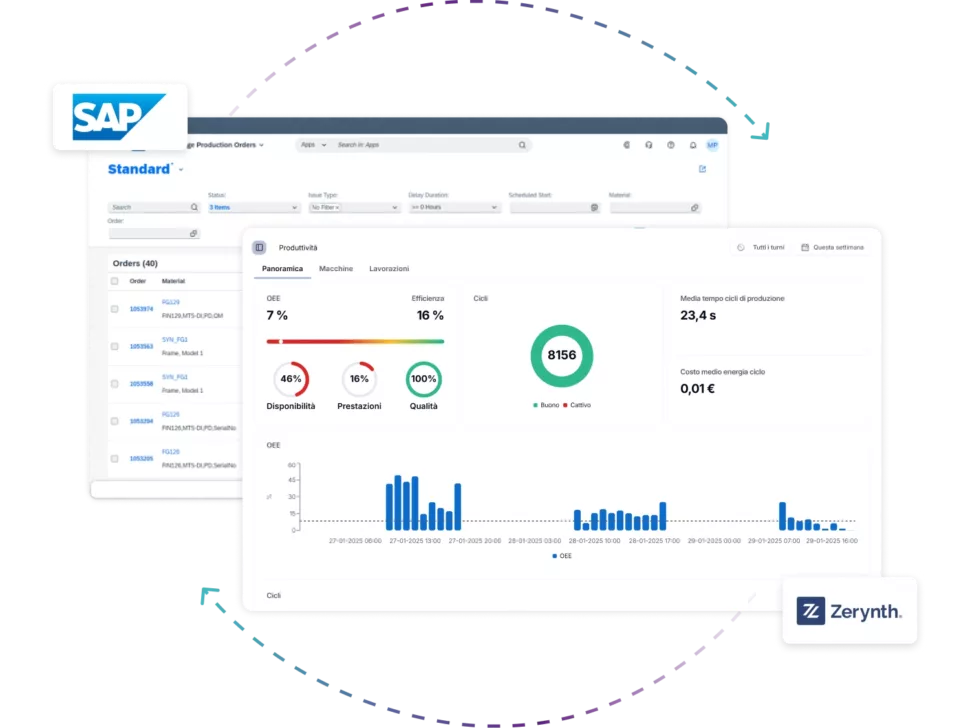

Configurable KPIs

tailored to specific production lines or facilities

How It Works – End-to-End

Typical Use Cases

Turn your machine data into a real-time competitive advantage: