Having Data Isn’t Enough to Make

Smart Decisions

Many businesses collect data but lack the models needed to extract value. Zero analyzes data in real-time, converting it into actionable insights to help you:

Reduce Downtime and Waste

Minimize idle time and optimize resource usage

Boost Efficiency and Productivity

Maximize operational performance

Save Energy

Optimize energy consumption

Make Data-driven Decisions

Enable real-time, data-informed choices

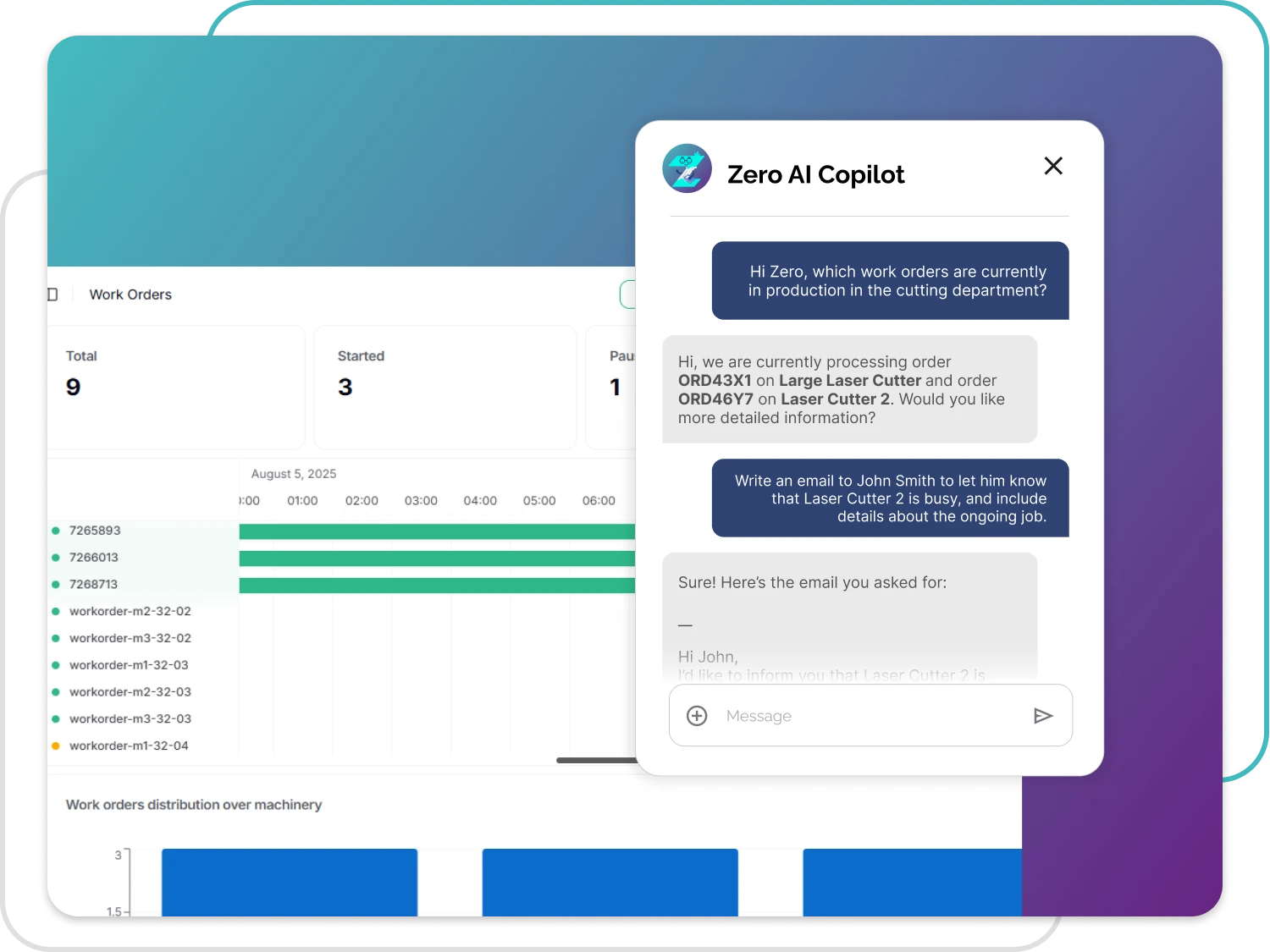

AI at the Service of People

All the power of Industrial AI with Chat-like simplicity

Zero integrates seamlessly into your factory and collaborates effortlessly:

What Can Zero Do for You?

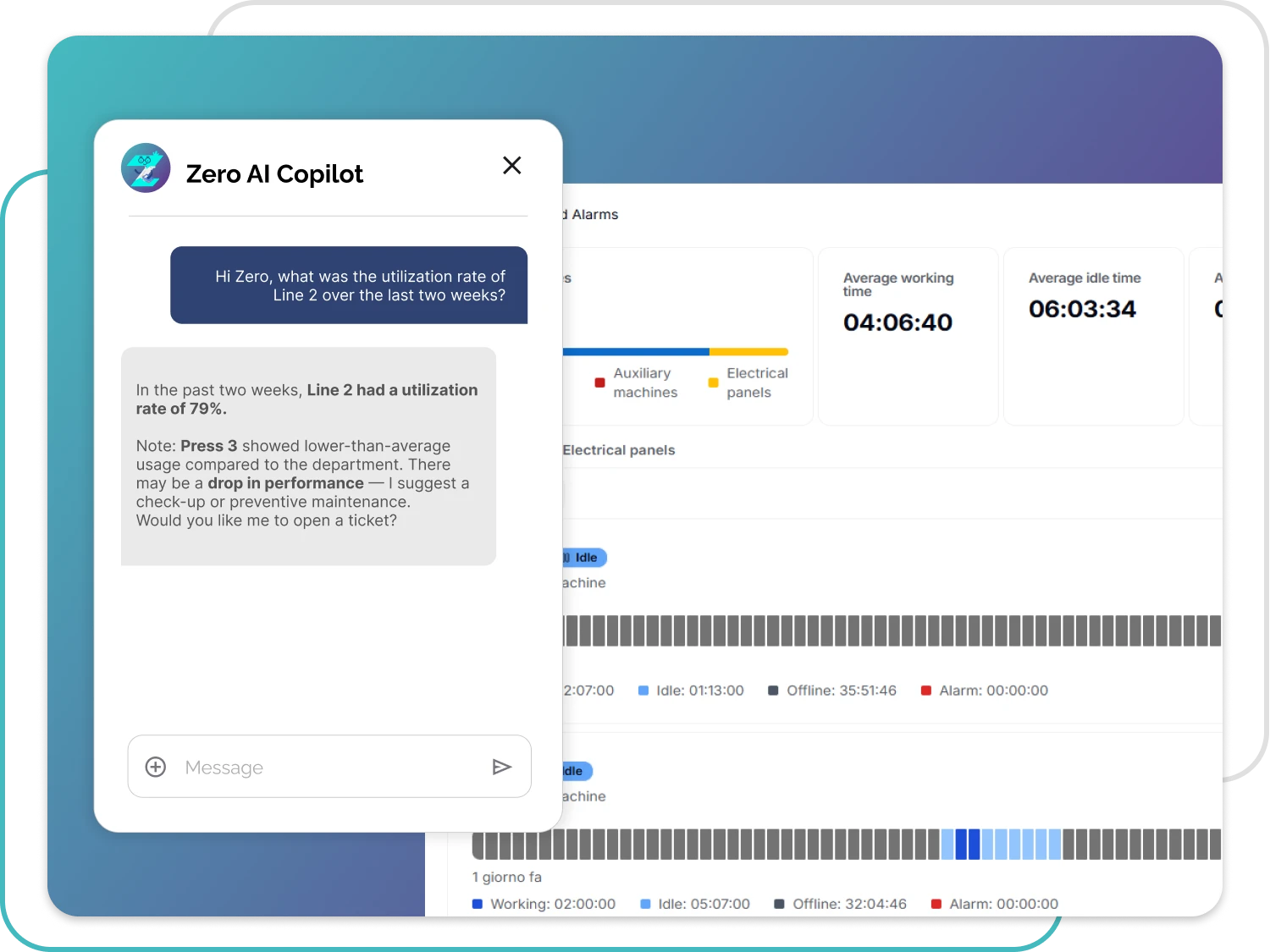

From Reactive Maintenance to Proactive Intelligence

Monitor your machinery, predict downtime, and act instantly

Zero empowers AI-driven proactive maintenance, reducing unexpected downtime by up to 70%

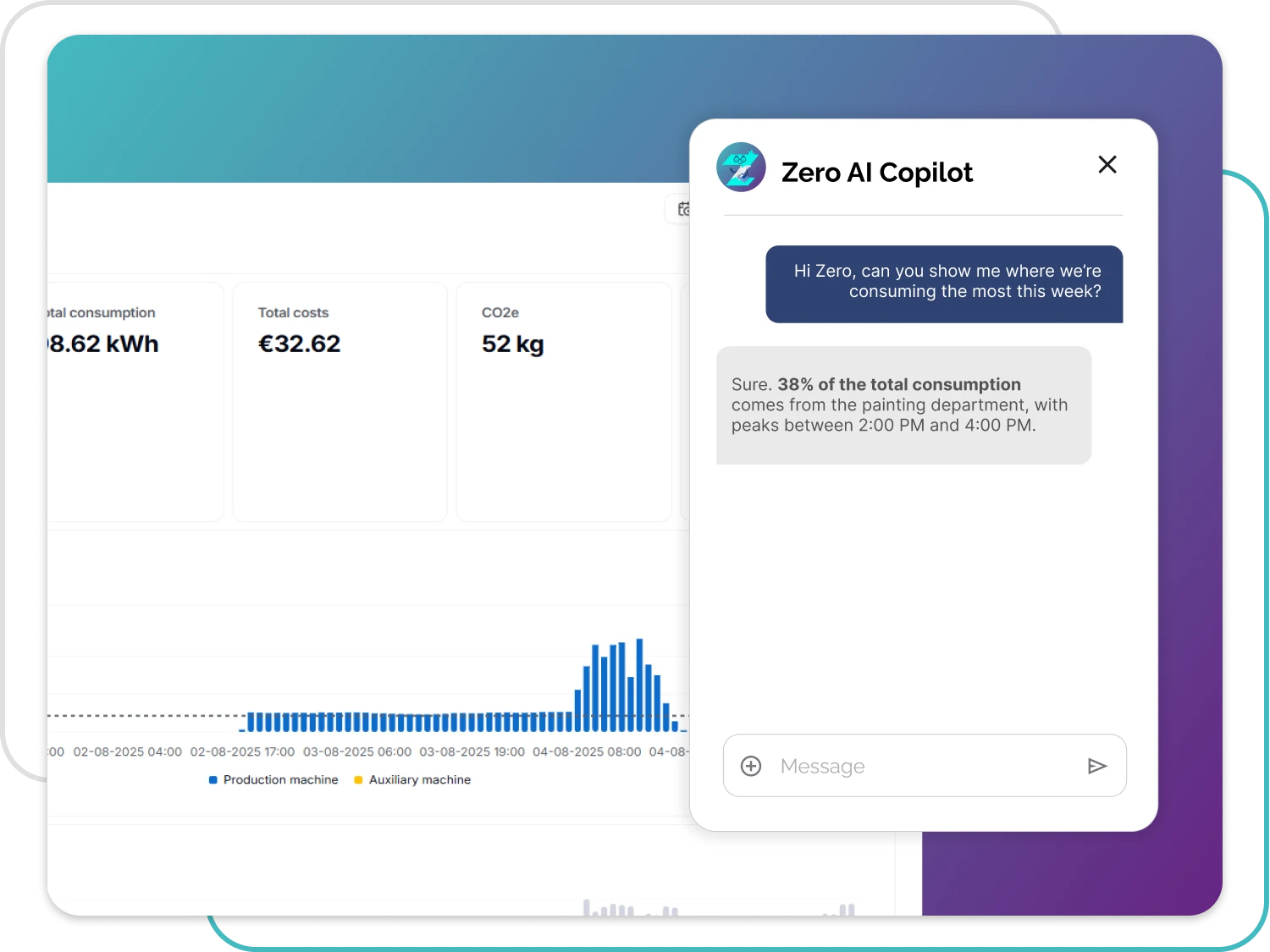

From Passive Consumption to Strategic Energy Flow Analysis

Gain clear insights into your factory’s energy usage and let Zero guide you towards energy savings

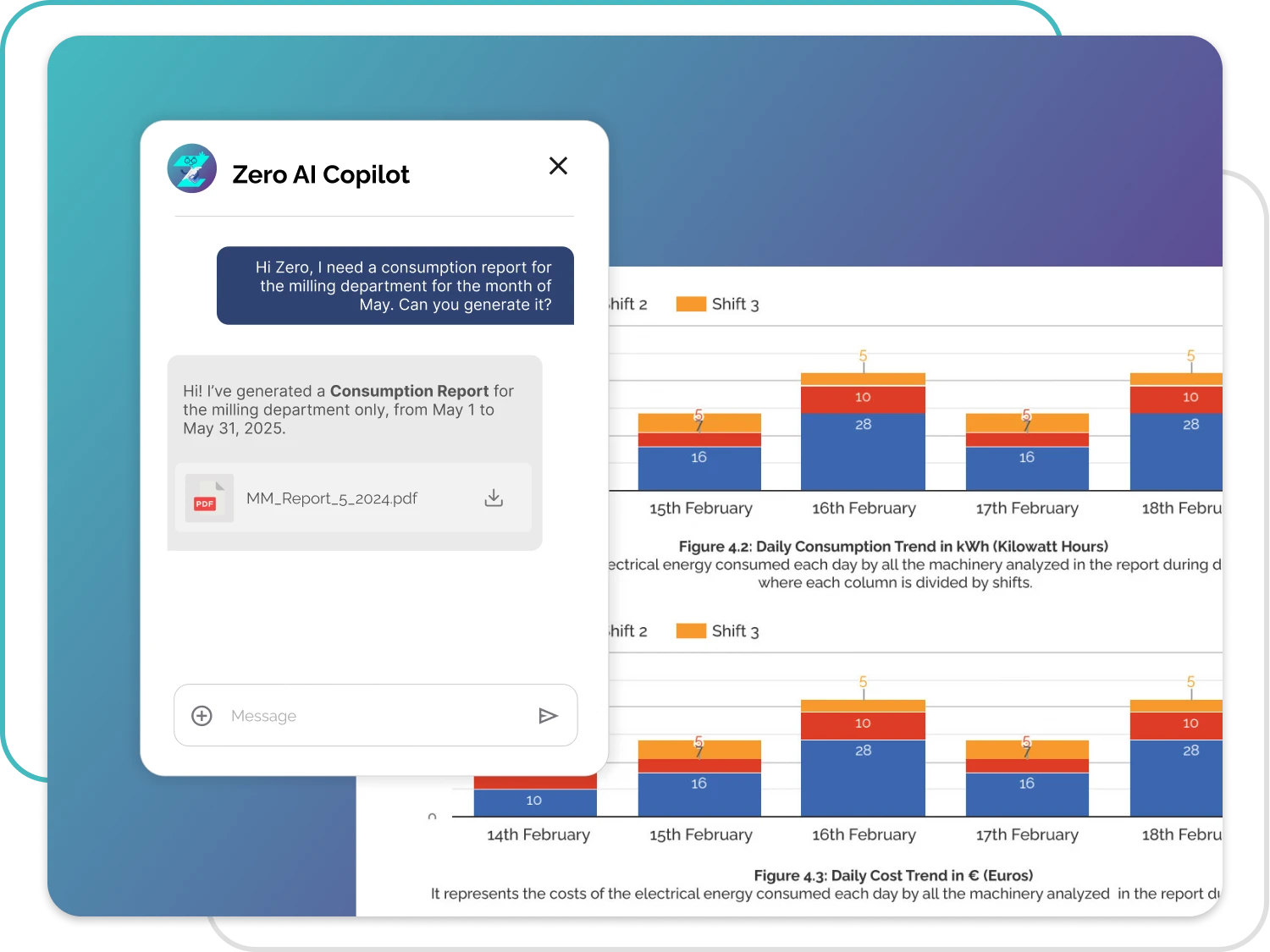

Save Time with Smart Reports

Generate automatic reports in seconds with detailed insights into production, maintenance, and energy usage. Save hours of manual work and eliminate human errors

ESG Reports Maintenance PlansEnergy Budgets

Maximize Your Existing MES and ERP Systems

Effortlessly enhance your current systems’ intelligence