Zerynth Connector for Bravo Manufacturing

Real-time machine data. Full control over production, planning, and costs.

Connect the Zerynth Platform to Bravo MES—designed for SMEs—in just minutes. Capture data from any machine, even legacy equipment or systems without a PLC, and sync it automatically with your MES. No manual inputs, no spreadsheets.

What You Can Do with the Zerynth x Bravo Connector

Key Features

Why Zerynth

Plug & Play on any machine

Works even on older equipment or systems without PLCs. No changes to your existing infrastructure.

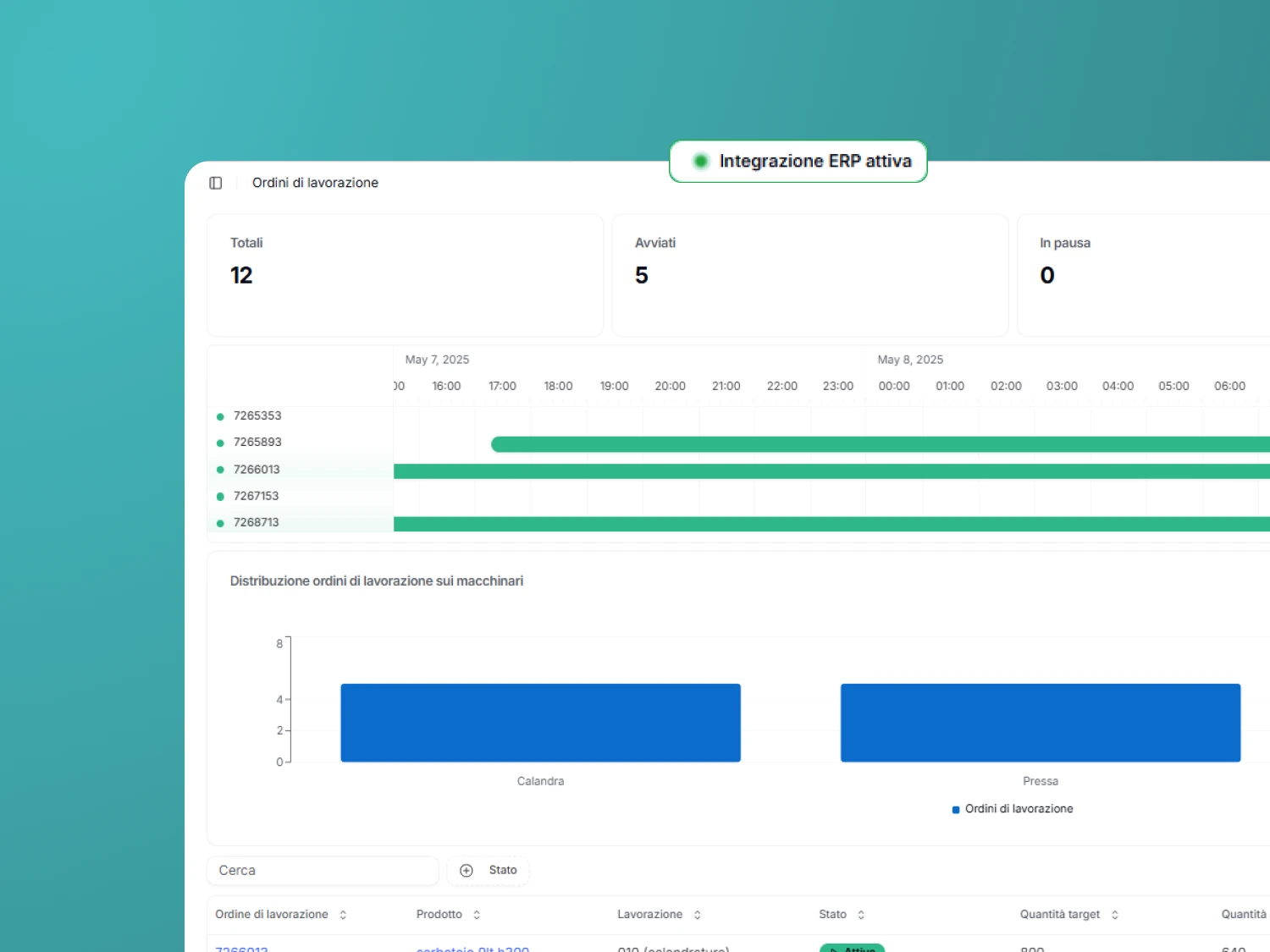

Native integration with Bravo MES

Machine data is automatically collected and pushed into Bravo—with no manual effort or risk of error.

marter production and scheduling

Spot bottlenecks early, improve scheduling accuracy, and keep production on track at all times.

Complete control over energy and costs

Monitor energy usage and power Bravo’s costing module with real, reliable machine data.

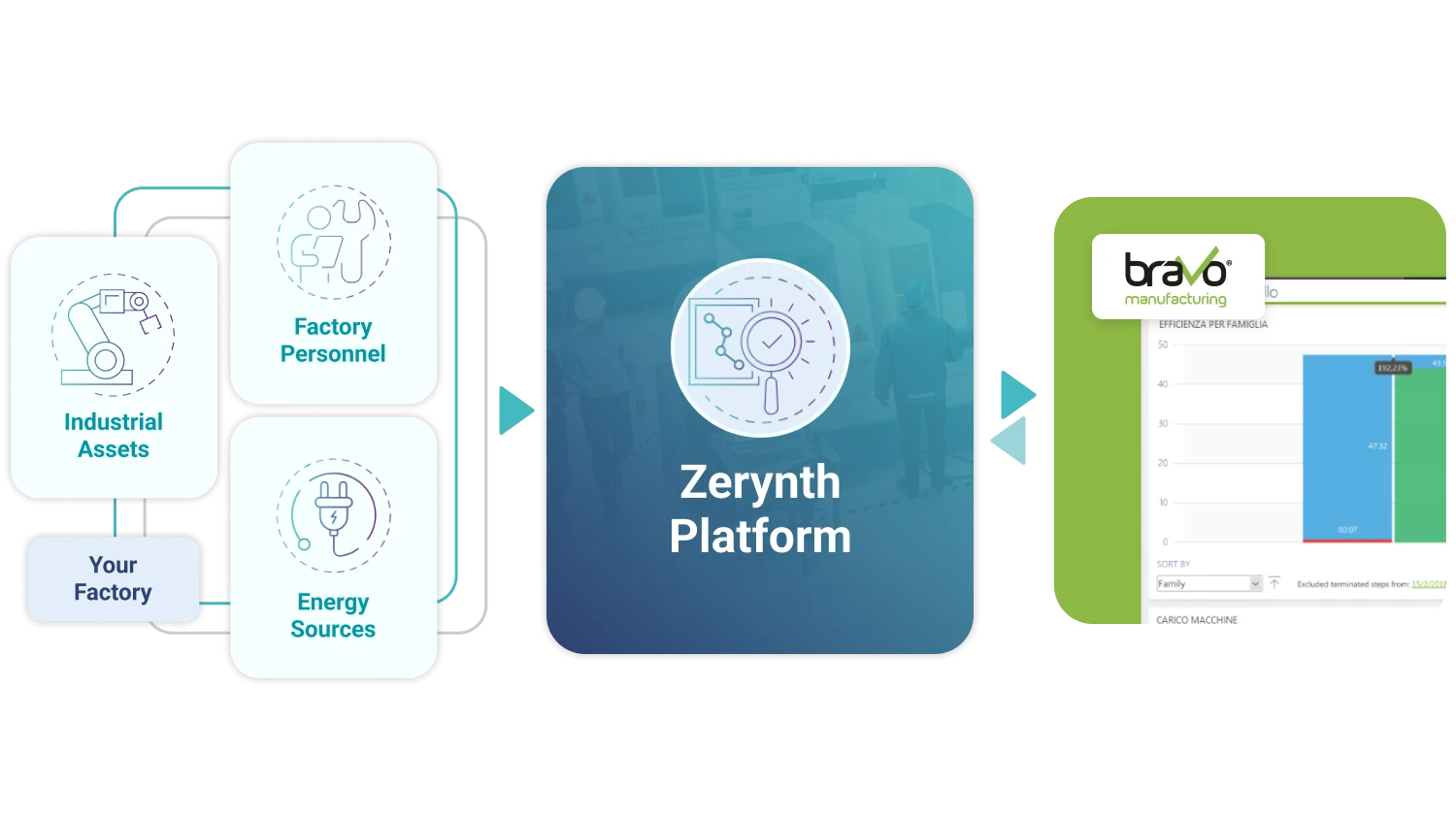

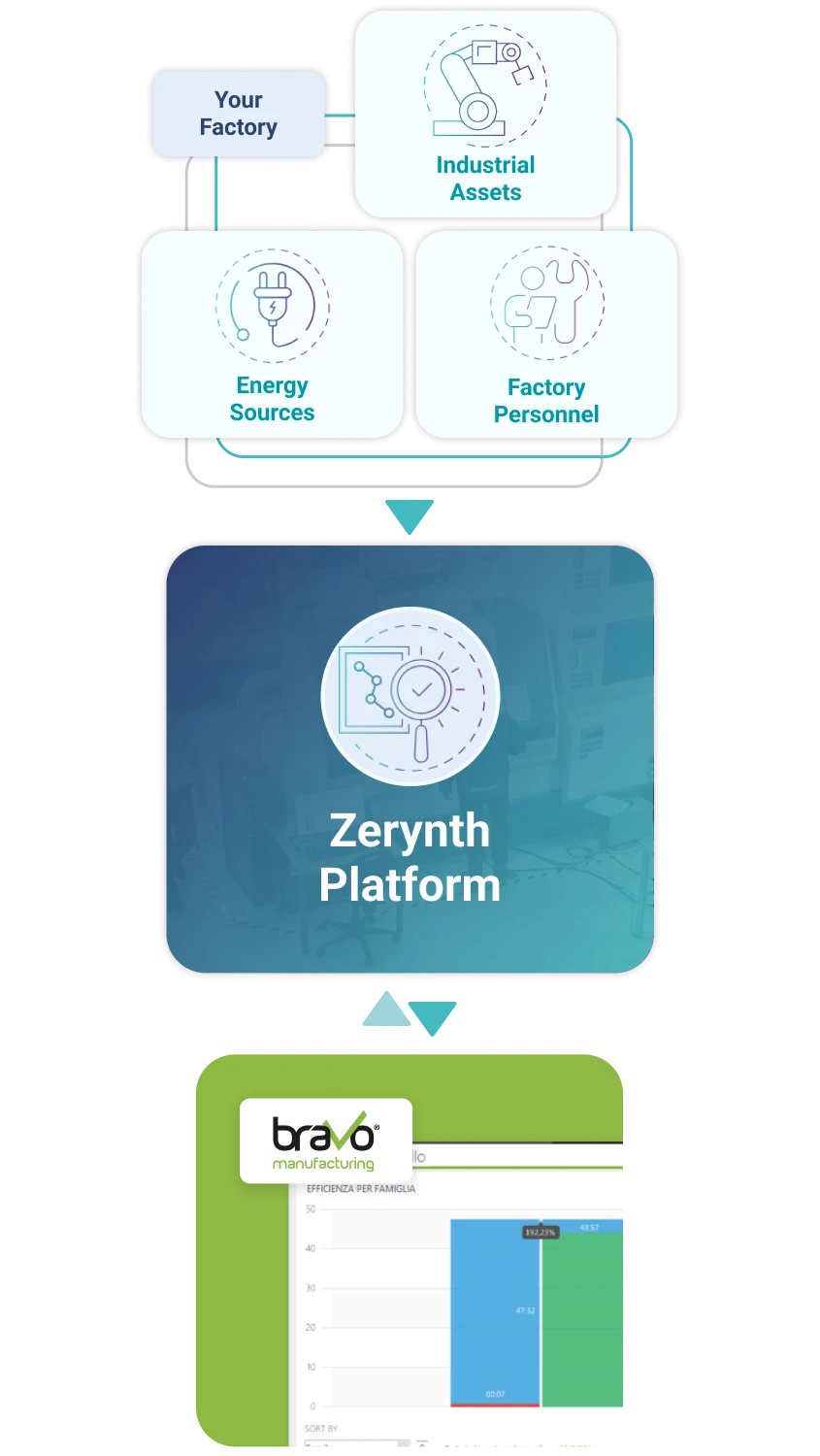

How It Works – End-to-End

A fast, simple path to connect your machines to Bravo MES.

Typical Use Cases

Turn your machine data into a real-time competitive advantage: