Connettore Zerynth per Infor CloudSuite Industrial

From the shop floor to the ERP: more control, fewer errors.

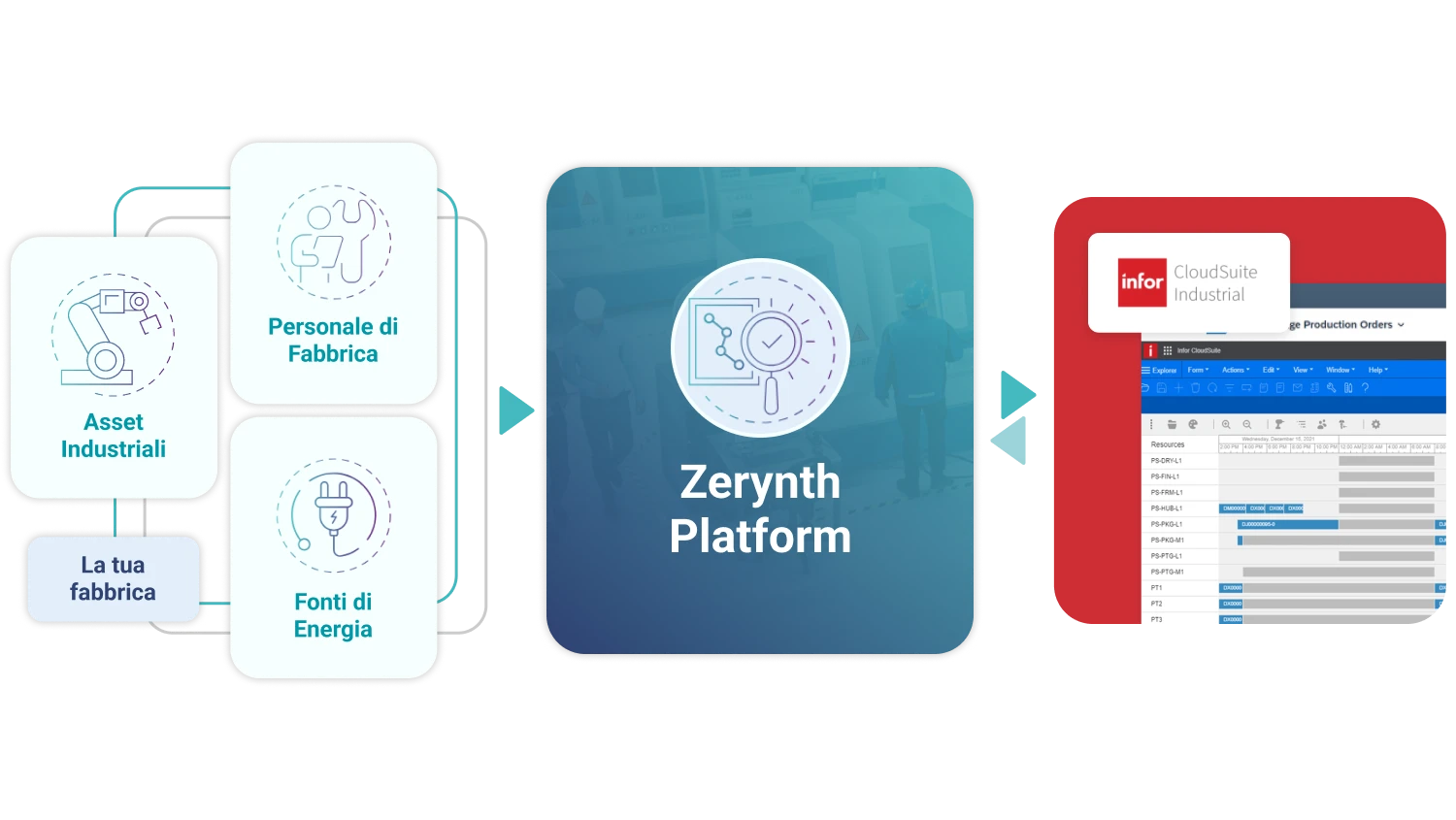

With the Zerynth Connector for Infor, production data flows directly into your ERP, eliminating manual data entry. Every machine — even legacy ones — becomes an integral part of your connected factory: greater operational efficiency, full traceability, and faster response to changing demand.

What you can do with the Zerynth – Infor Connector

The Zerynth Connector for Infor CloudSuite Industrial automates data flow between machines, even older ones, and your ERP, allowing you to:

Key Features

Why choose Zerynth?

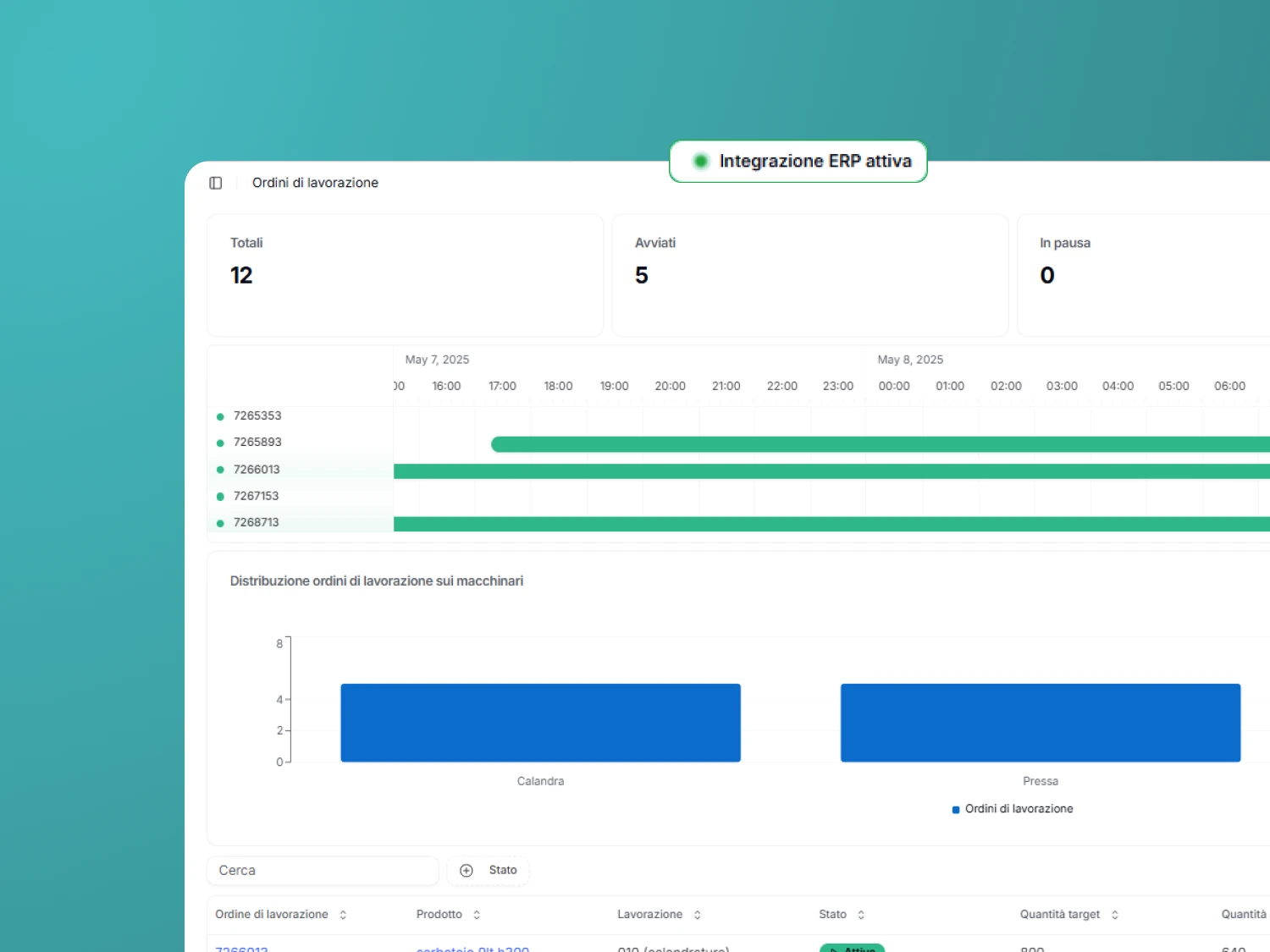

Eliminate data entry and align ERP with the shop floor

Fewer errors, more accurate planning, reduced downtime.

Monitora i consumi energetici

Dati pronti per accedere agli incentivi del Piano Transizione 5.0.

Plug & Play Digitalization

Retrofitting on existing equipment with no hardware modifications.

Ottimizza la Produzione

Dati aggiornati per MRP e APS

How it Works: End-to-end

A fast and simple process to integrate your machines with Infor

Easily integrate your data with Infor CloudSuite Industrial

Ally Consulting is one of the official Infor providers we partner with to simplify data integration from your machines into Infor CloudSuite Industrial.

A partnership designed to enable fast, simple, and reliable digital manufacturing.

Use Cases

Gain a competitive edge by turning your production data into real-time operational insights.