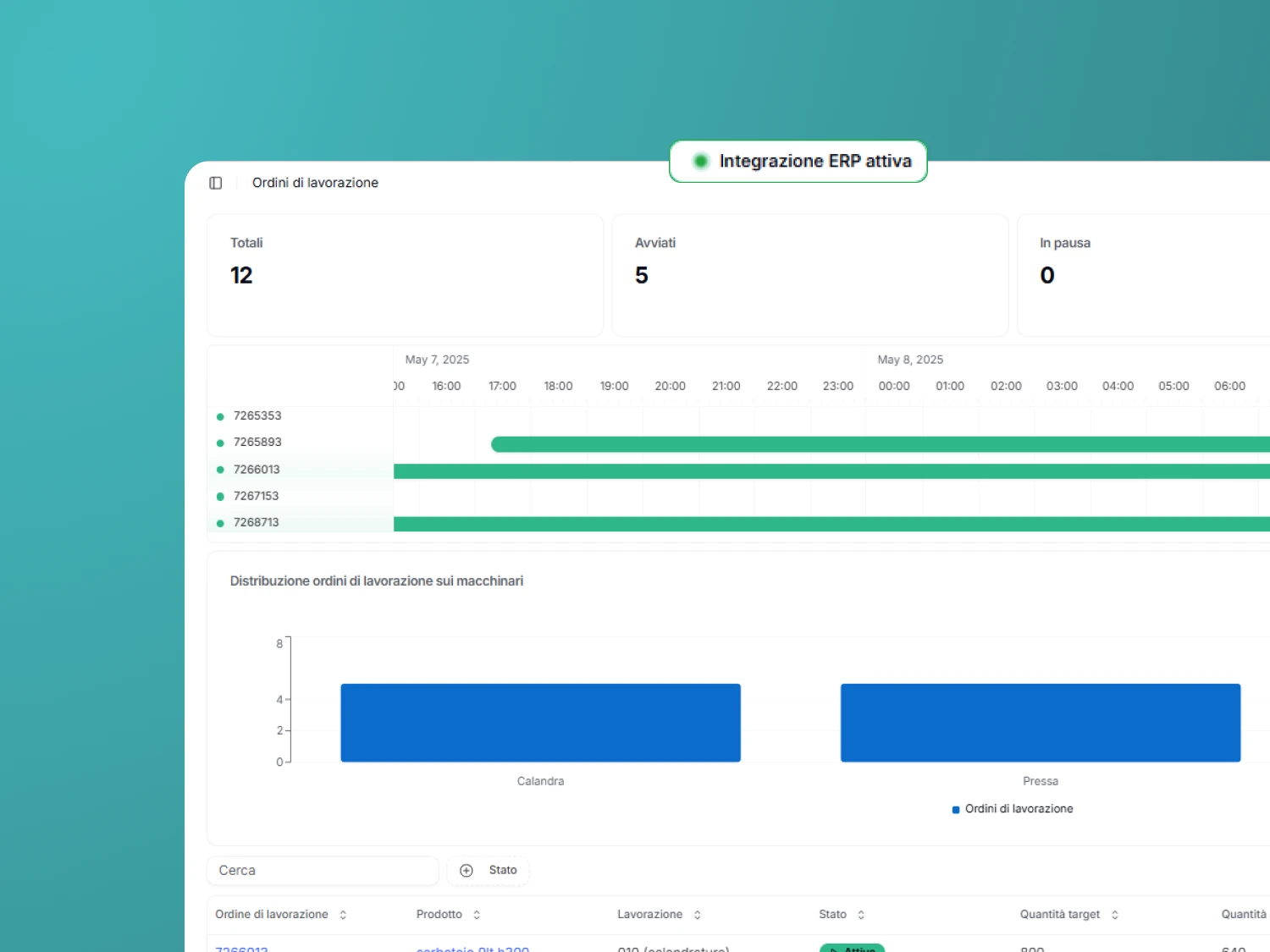

Zerynth Connector for Microsoft Business Central

Keep your production and ERP perfectly in sync, — in real time.

Connect your industrial machinery to Microsoft Business Central and automate the flow of production data. Gain faster, more accurate, and scalable decision-making across your operations. Automation, control, and operational continuity — for manufacturers of every size.

What You Can Do with the Zerynth Connector

Key Features

Why Zerynth?

Non-invasive, plug & play installation

Quick setup using a current clamp and dry contact. No machine downtime or modifications required.

Reliable data for faster decisions

Get real-time insights to plan, react, and optimize. Signals, consumption, and process parameters are captured and securely sent to the Zerynth Cloud.

ERP/MES ready

Fully compatible with Microsoft Dynamics APIs. One unified data source for production, quality, maintenance, and supply chain management.

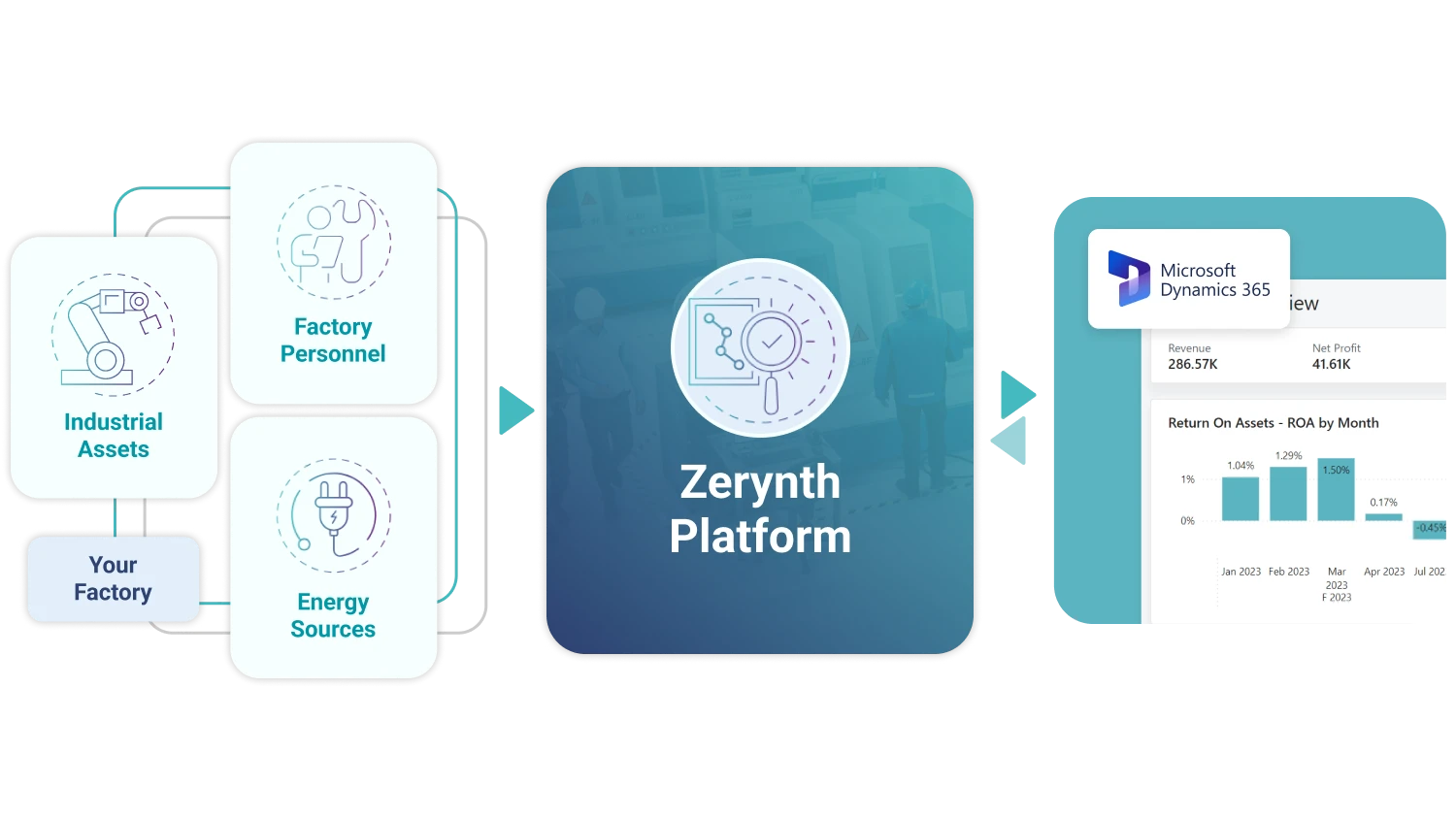

How It Works – End-to-End

Typical Use Cases

Turn your machine data into a real-time competitive advantage: