Connect every machine to Zeta MES without stopping production.

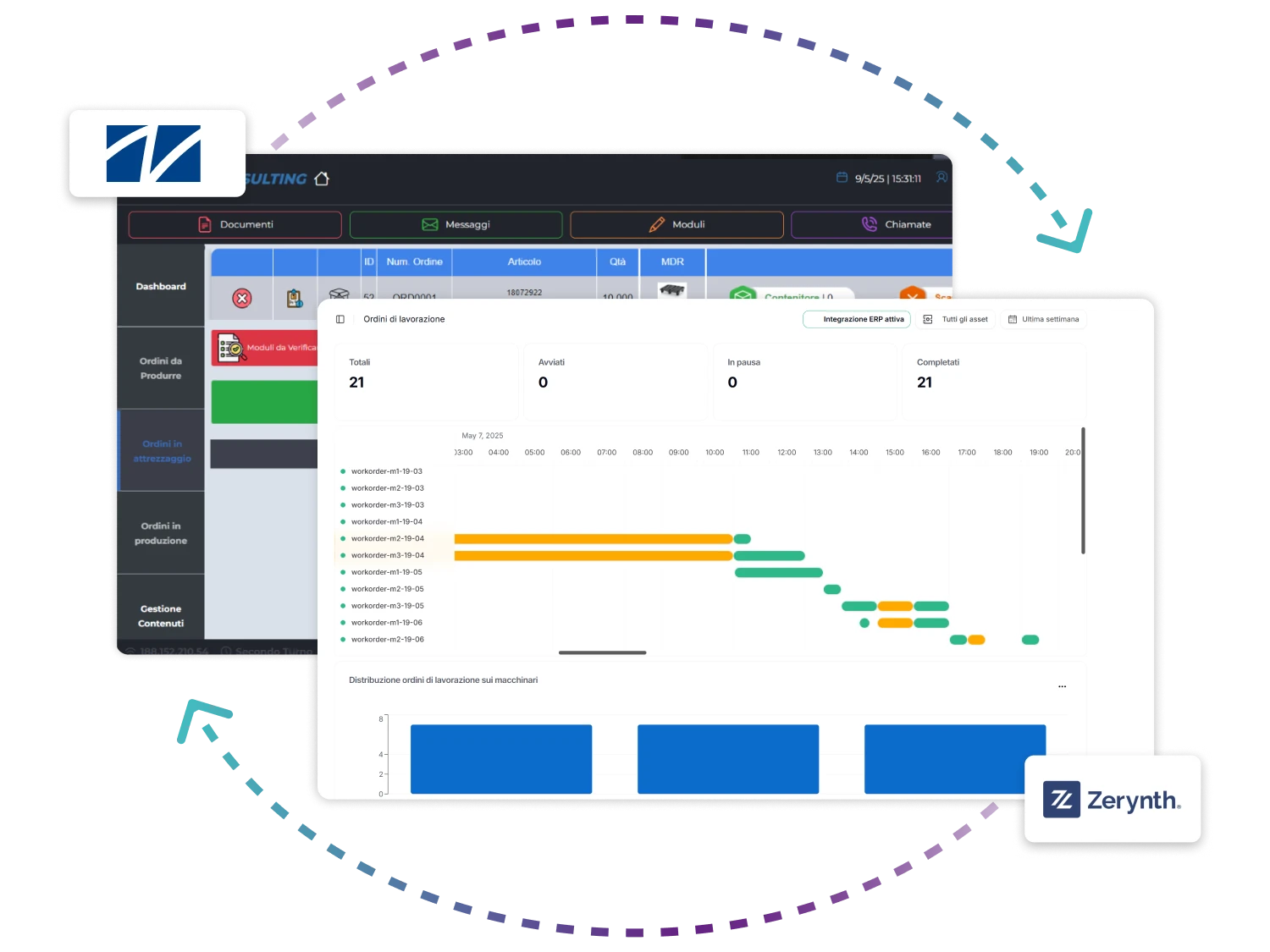

The Zerynth Connector for Zeta MES enables direct communication between industrial machinery – even those without native connectivity – and Zeta Consulting’s MES platform. Zerynth devices collect real-time data (energy, cycles, downtime, parts produced) and send it to the MES, which integrates it with all operational functions: production, quality control, tooling check lists, batch traceability, dematerialisation of machine/workstation documentation, messaging, production analysis

The result?

An interconnected factory where data becomes decisions, and every process is visible end-to-end.

Why choose Zerynth?

Plug & Play Connectivity

Even machines without native connectivity can communicate with Zeta MES in just minutes.

Integrated Energy Monitoring

View real-time consumption by plant, line, and machine.

Fast Retrofitting

Install, capture, integrate: all without stopping production.

Native ERP Integration

Data collected from the field is synchronized with your ERP for complete process traceability.

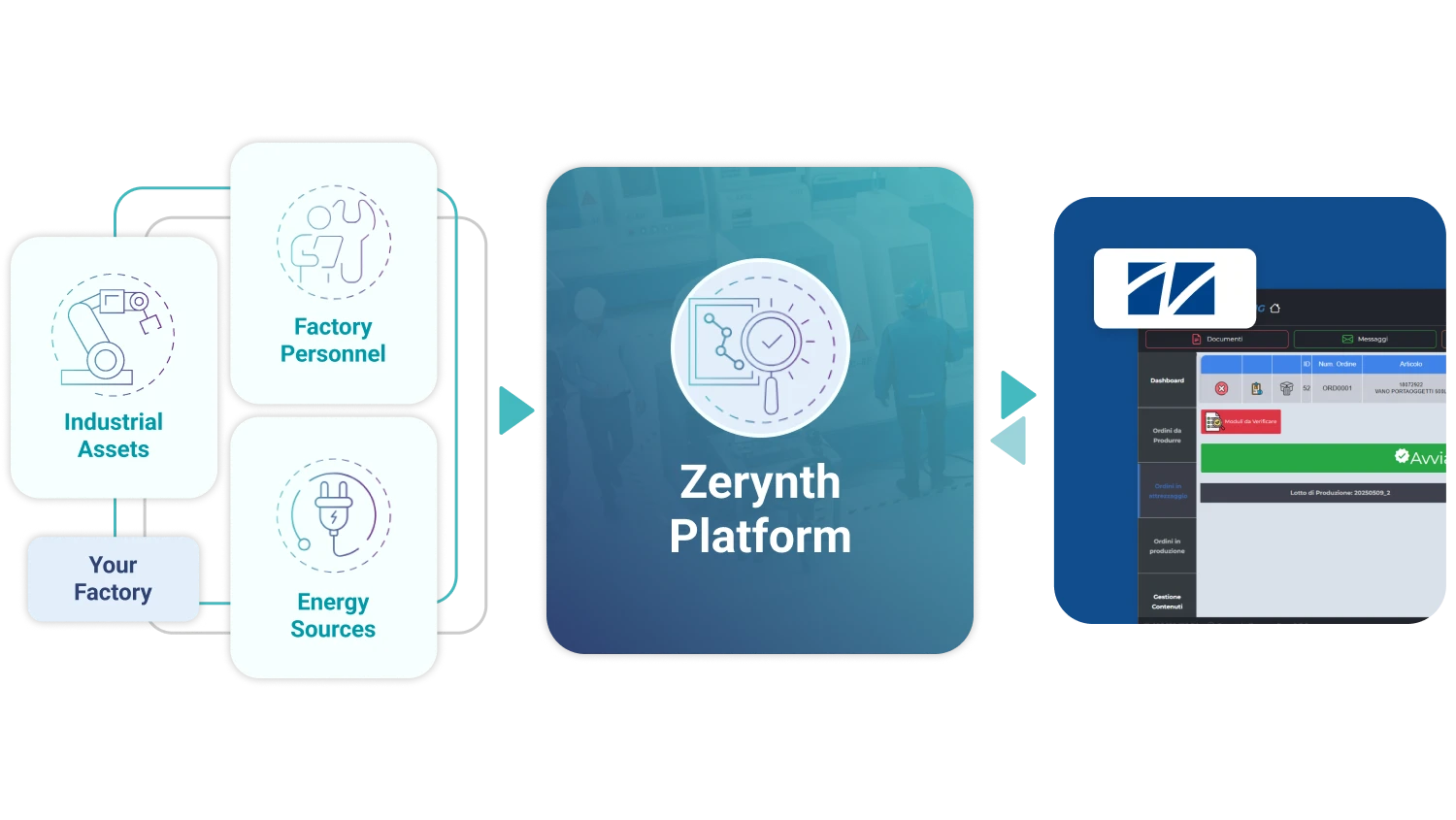

How it works: End-to-end

A simple and fast process to integrate your machinery with Zeta MES

Case Study

A successful digitalization project in partnership with Zeta Consulting