Prevention is better than downtime

Zerynth’s Anomaly Detection feature analyzes machine data and operational KPIs in real time to identify unusual patterns or trends. Smart notifications warn you in advance, helping you act before issues affect production.

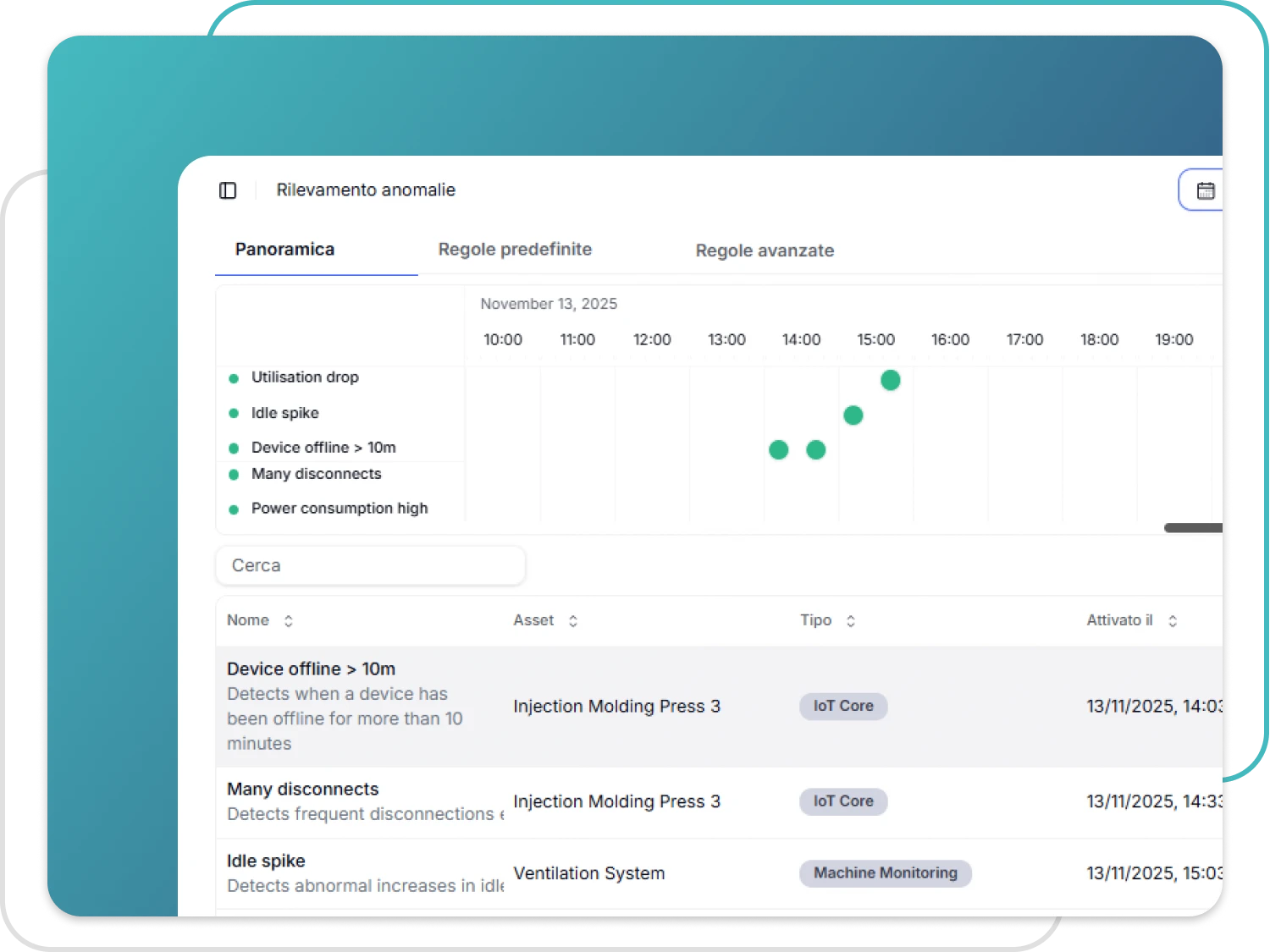

Smart Anomaly Detection

Powered by AI-based detection models, the system compares real-time data with expected parameters (e.g., machine stops, energy usage, production cycles, run times, etc.) and highlights any significant deviations.

Smart and fully customizable alerts

Start with predefined thresholds, then create custom rules and conditions tailored to each operational team.

What can you achieve with Zerynth Anomaly Detection?

Reduce rework time

Act in real time on machine-side anomalies caused by unexpected stops to cut rework time on products.

Optimize extraordinary maintenance

Receive automatic notifications when critical thresholds are exceeded and streamline extraordinary maintenance management.

Increase productivity

Quickly identify idle or underperforming machines to optimize cycle times and boost productivity.

Make the most of your energy

Monitor waste and energy/power anomalies to improve efficiency and sustainability across your processes.

When it happens, you know it

Your anomaly detector, connected to everything that matters

Easily integrate the module with your industrial systems (MES, ERP, CMMS) and automate notifications on your preferred channels (email, platform, Google Chat, etc.).

Zerynth’s Anomaly Detection speaks the language of your factory and is built for people in the field—technicians, maintenance teams, and operators.

No learning curve, no coding. Just results.