An attack that hits IT systems can slow down an office. An attack that involves machinery and logic controllers can block a line, generate waste, and halt entire shifts

It is this difference that makes industrial network security a strategic theme for those managing production processes. The stakes are not just digital: they concern continuity, quality, and physical safety.

How an industrial network works

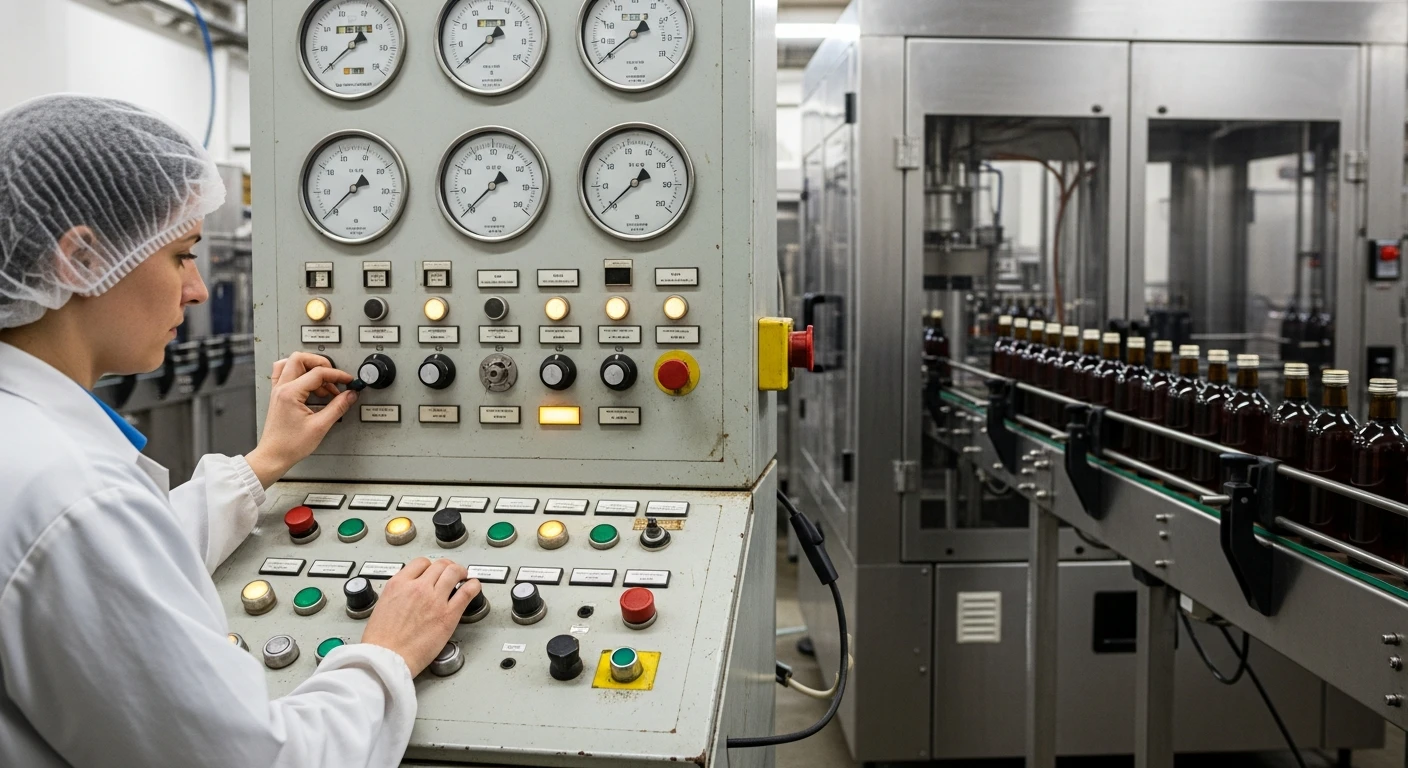

Industrial network security, also called Industrial Cybersecurity, is measured by the capability to protect systems that control physical operations. In an OT environment, PLCs, sensors, robots, and machines exchange commands that regulate continuous production cycles. Machines cannot be rebooted lightly, and many plants have real-time cycles that tolerate only milliseconds of delay.

Making industrial OT security complicated is the technological variety typical of the sector: new machines coexist with very dated models, protocols born without any protection function run alongside modern IoT solutions, and the network is often expanded to integrate ERP or MES without a review of the overall architecture.

Why industrial networks are vulnerable and how attacks occur

Vulnerabilities often arise from the very structure of the plants. Industrial protocols used in many factories do not include encryption or authentication. Networks are still poorly segmented today and, in practice, a single weak point can propagate an incident across multiple machines.

It is for this reason that factory network security requires a different approach from the IT one. The most frequent attacks aim to interrupt production. Ransomware hits MES servers and planning systems, stopping shifts. In other cases, PLC parameters are modified without authorization, causing waste or unexpected changes in cycles. Variations in consumption or machine states are among the first signals, and represent an essential element for factory cybersecurity.

The problem is not just technical complexity: it is production continuity. Protecting OT means preventing measurable operational impacts, and for this reason, it is becoming an increasingly important aspect for digitized companies.

Why IT tools are not enough

Traditional IT technologies are not compatible with OT, not due to ineffectiveness, but due to operational nature. Antiviruses cannot be installed on PLCs. Monitoring agents do not work on embedded systems. Updates cannot be applied without planning a line stop. In many cases, an overly aggressive IT firewall can block packets necessary for the functioning of a machine.

For this reason, industrial network security requires methods based on segmentation, access control, and behavior observation, rather than on invasive tools designed for laptops or servers. OT protection is a continuous balance between security and continuity.

The role of regulations

Regulations like IEC 62443 and NIS2 help make industrial OT security structured.

The IEC 62443 provides principles on segmentation, zones, security levels, and requirements for components and integrations. The NIS2 introduces concrete obligations to control access, monitor risks, and demonstrate adequate measures in the industrial scope.

These references do not require a deep technical background, but define a useful framework to guide decisions and investments.

How to build an effective OT defense

A solid path starts with visibility. Knowing which devices are connected, which protocols they use, and who can access them is the base of industrial network security.

In many factories, there are devices that are uncensused or added over time without an overall design. Segmentation noticeably reduces the propagation of an incident.

Separating lines, departments, or critical systems is a simple and effective intervention. Remote access, indispensable for maintenance, must be managed with temporary credentials, strong authentication, and controlled sessions.

Continuous monitoring of behaviors is another decisive element: anomalous consumption, incoherent cycles, and variations in machine states are indicators that allow timely interventions, increasing the overall robustness of factory cybersecurity.

IoT, edge, and AI as elements of protection

IoT does not just bring complexity: if implemented correctly, it increases the quality of factory network security. Modern edge devices, like Zeroboxes, use cryptographic identification, secure connections, and traffic isolation. They act as a filter between machines and the cloud and allow for reducing network exposure.

AI adds advanced observation capabilities. It recognizes anomalous patterns, correlates events, and offers operational support even where an internal IT department does not exist. This significantly strengthens industrial OT security, especially in contexts with little technical personnel.

Recurring errors in factories

Many incidents arise from daily habits rather than sophisticated attacks. Wi-Fi shared between industrial devices and personal smartphones, passwords noted near electrical panels, remote access left open after an intervention, and non-segmented networks are common conditions. Correcing these aspects is one of the fastest ways to improve OT security without complex investments.