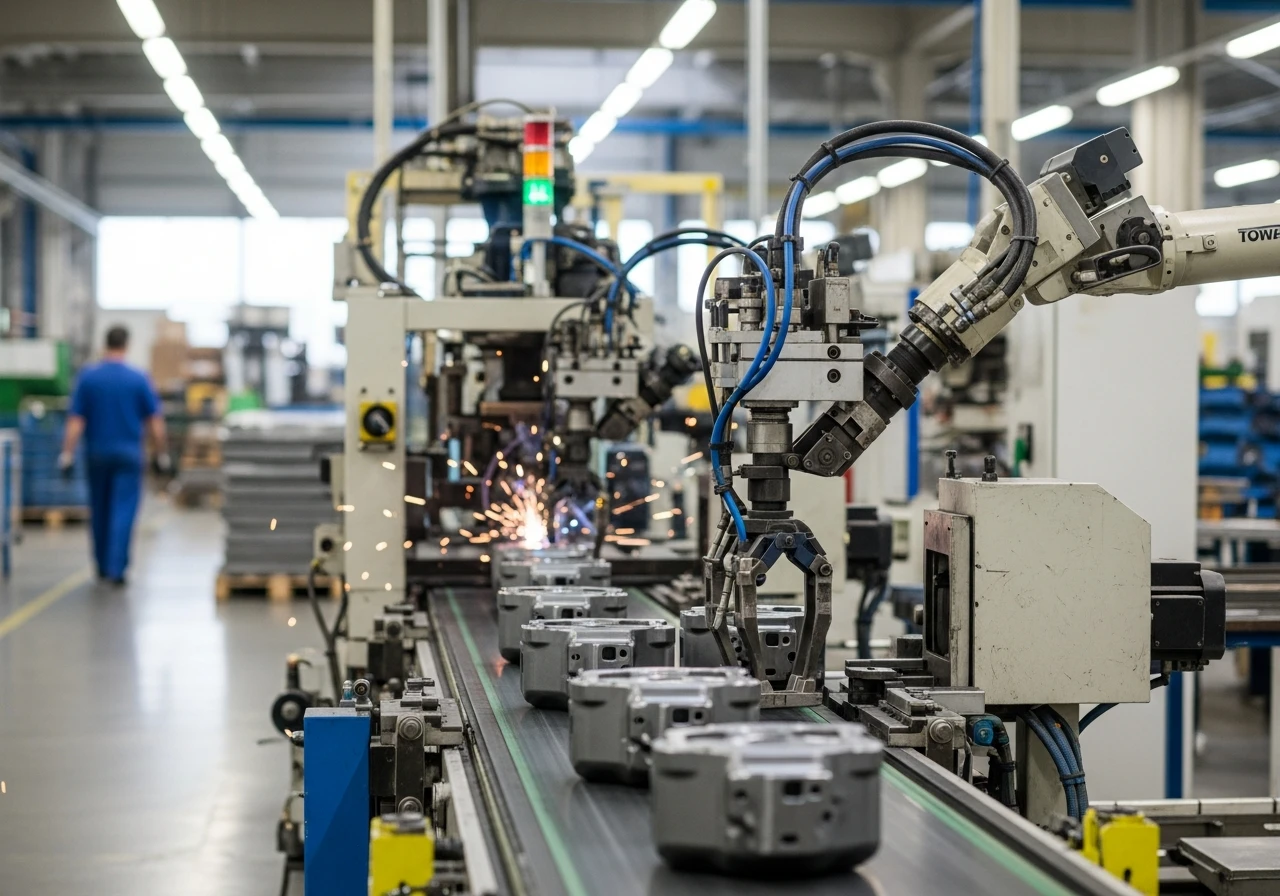

Until a few years ago, talking about Artificial Intelligence in the factory meant evoking futuristic scenarios or investments only accessible to industry giants. Today, the narrative has changed, but confusion often remains about what this technology truly is when it descends to the production plant level.

For a manufacturing company, AI should not be considered a digital “gamble” or a simple software to install. It is a technological system in all respects. And like any new tool introduced into the workshop – whether it’s a machining center or a logistics system – it requires an implementation strategy, a setup phase, and a training path for those who will use it.

The goal is not to chase a trend, but to solve a problem that the computerization of factories has created: the excess of information that often slows down, instead of speeding up, decisions.

In this article, we analyze how an Artificial Intelligence system for SMEs can transform from a cost into a strategic asset, filtering the data noise to concretely support people’s work.

A Support System, Not a Crystal Ball

Many companies have already faced a first phase of digitalization, interconnecting machinery and bringing data to dashboards. The result? Production managers often find themselves submerged by graphs and notifications, struggling to distinguish true priorities.

The value of an AI Copilot lies in its ability to act as an intelligent filter. It is not a program that “does everything on its own” as soon as it’s turned on: it is a tool that must be configured to learn the factory’s normal behavior.

Once fully operational, the system works in the background and supports the operator, signaling only significant deviations (a vibration anomaly, an off-scale energy consumption) that would escape manual control. In practice, it doesn’t replace technical experience: it enhances it.

The Prerequisites: Data Culture and Process

There is a myth to dispel: to adopt AI, you don’t need a perfect “Smart Factory.” However, AI does not work in a vacuum. To generate value, the system must be fed correctly.

An effective AI for SMEs strategy does not start with the algorithm, but with the availability of data. If machinery is isolated, AI cannot help. The technical prerequisite is to have a flow of data, even minimal but constant, coming from the department.

But there is an even more important prerequisite: the cultural one. Introducing AI means training staff to no longer rely solely on intuition, but to trust the objective data provided by the system. It is a change management journey that must be handled with care.

How to Start with Industrial AI: A Phased Approach

The most common mistake is thinking of AI as a “turnkey” package that solves everything immediately. The sustainable route is the incremental one. Here is a concrete roadmap to understand how to start with Industrial AI:

Objective Definition (The “Why”)

Identify a recurring and costly problem (e.g., unplanned downtime on a critical line or high scrap rates). The system must address a precise business need.

Connectivity and Acquisition (The Infrastructure)

Before intelligence, visibility is needed. It is necessary to ensure that the machines involved transmit data. If the machine fleet is dated, IoT gateways can be used to extract signals without changing the machinery.

Implementation and Training (The Human Factor)

This is the crucial phase. Once active, the system will start providing insights. This is where training comes into play: operators and maintainers must learn to interpret the AI’s signals and integrate them into their daily routines. AI becomes useful over time, as the team learns to interact with it.

Analyzing the Cost of AI in a Company: The Investment Over Time

When evaluating the economic impact of an AI implementation for your company, you need to change your perspective. It is not a one-time expense like buying a PC, but an investment in a continuous efficiency process.

Modern solutions allow starting with pilot projects on restricted perimeters. This reduces the initial risk and allows testing the system’s effectiveness on a single production island.

If the implementation leads to a reduction in faults or energy waste, the generated savings finance the extension of the system to other departments. Industrial AI must demonstrate its ROI (Return on Investment) in the field.

Zero: Technology at the Service of Competencies

At Zerynth, we developed Zero with this philosophy. It is not software that adds complexity, but a system designed to simplify access to information.

Zero allows technicians and managers to query production data in natural language, obtaining answers filtered from the background “noise.” It is a tool that requires guided implementation, but once it enters the operational routine, it becomes an indispensable ally for solving modern production challenges.