Industrial AI

Artificial Intelligence for Industrial SMEs: Costs, Advantages, and First Steps

Until a few years ago, talking about Artificial Intelligence in the factory meant evoking futuristic scenarios or investments only accessible to industry giants. Today, the narrative has changed, but confusion often remains about what this technology truly is when it descends to the production plant level. For a manufacturing company, AI should not be considered a digital "gamble" or a simple software to install. It is a technological system in all respects. And like any new tool introduced into the workshop – whether it’s a machining center or a logistics system – it requires an implementation strategy, a

From Data to Intelligence: How to Build a Connected and Smart Factory

A smart factory starts from a clear need: understanding what truly happens on the shop floor. Machine states, energy usage, cycle times, product quality Many companies already collect data, but it often remains scattered across files, disconnected software, or handwritten notes. The result is a fragmented view that slows down decisions, analysis, and improvements. A smart factory gives a precise and real-time picture of performance, bottlenecks, and waste. This visibility is no longer optional. It’s essential for improving productivity and efficiency, a theme highlighted in our analysis of Italian manufacturing competitiveness. The Digital Path: From Data Collection

How Artificial Intelligence in the Factory Is Transforming the Work of Operators, Technicians, and Managers

Artificial intelligence in the factory is revolutionizing how people and technology interact. It’s no longer just about automation, but about collaboration with intelligent systems that can analyze, predict, and suggest actions. Many companies are exploring AI, but the real challenge is moving from intention to implementation. Zerynth helps manufacturers turn data into a daily strategic resource. We embrace a collaborative approach: AI that enhances human work, improving decision-making, safety, and productivity. This collaborative artificial intelligence model differs from traditional automation because it keeps human experience and judgment at the center. The New Role of Senior Operators Senior operators

Artificial Intelligence in Manufacturing: 2026 as a Turning Point for Italy and Europe

The European manufacturing industry is on the brink of a new revolution: artificial intelligence is no longer a promise but a real driver of growth, resilience, and competitiveness. In 2026, AI becomes an integral part of industrial strategies. Italian and European companies will no longer see it as an isolated optimization tool, but as a pillar of digital and production transformation. From Automated to Intelligent Factories Today’s industrial landscape is complex: high energy costs, fragmented supply chains, sustainability pressures, and the need for greater productivity.In this context, artificial intelligence in the manufacturing industry becomes the engine of a profound transformation

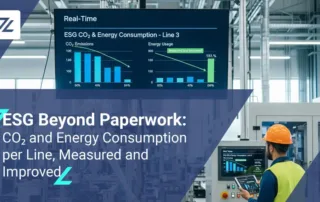

ESG That Doesn’t Stay on Paper: CO₂ and Energy Consumption per Line, Measured and Improved

Discover how one company turned energy and CO₂ data into actionable insights — reducing the environmental impact of each production line while improving energy efficiency, sustainability, and ESG positioning. How can manufacturers gain visibility into the environmental impact of their production lines? Many companies today are working to reduce their environmental footprint and comply with Industry 5.0 and ESG regulations, yet they often lack precise visibility into energy use and emissions per line or machine.Energy consumption monitoring solves this problem by providing accurate data to set realistic and measurable targets. This case study shows how reliable data is essential

Visible Efficiency on Your Energy Bill: Reduce Energy Costs with Industrial Energy Monitoring

Discover how an industrial plant reduces energy costs by up to 40% without decreasing production. This case study shows how industrial energy monitoring tracks consumption in real time, identifies the most productive time slots, and applies immediate operational actions to optimize industrial energy efficiency and ROI. How much do energy inefficiencies impact plants today? In many plants, unproductive states are a significant source of energy waste. Without industrial energy monitoring data on cost per cycle and per machine, crucial questions often remain unanswered, making it difficult to optimize shifts and plan production efficiently. “How much do energy inefficiencies currently

From Breakdown Chaos to IoT Predictive Maintenance

In many manufacturing companies, the maintenance department still operates in a constant state of emergency. When a machine stops, a race against time begins to repair it, causing delays and inefficiencies in production. Implementing IoT predictive maintenance can transform this scenario. Why is maintenance always in emergency mode? Even when a preventive plan exists, it is often ineffective for several reasons: Rigid interventions – based on fixed intervals rather than real machine data. Premature or delayed maintenance – some tasks are performed too early, others only after a breakdown, causing machine downtime. Lack of real-time monitoring – managers have

How to Boost Productivity by Reducing Downtime: A Packaging Industry Case Study

Discover how an Italian SME in the packaging industry transformed its operations—shifting from a reactive to a proactive approach—thanks to the Zerynth platform for machine maintenance monitoring. What was the issue: why was production slowing down? A packaging machinery company in Italy was facing a critical challenge: No real-time visibility on machine status Difficulty identifying prolonged downtime Reactive instead of preventive maintenance Increasing waste of time and resources Production monitoring was entirely manual. The result? Slow decision-making, emergency fixes, and a negative impact on production optimization. How does smart rule-based monitoring work? To increase productivity and reduce downtime, the

Industrial AI Copilot or Conversational Agent? What they are and why they will transform the Industry

In the world of digital solutions for industry, the term "artificial intelligence" is on everyone’s lips. But what does it really mean to apply AI to the context of manufacturing? And more importantly, what is the difference between an Industrial AI Copilot and a simple Conversational Agent? If you’re a CEO, production manager, or industrial consultant, understanding this distinction is essential to optimize production processes, manage predictive maintenance, and leverage IoT and intelligent systems. Industrial AI Copilot vs Conversational Agent: what’s the real difference? In short, an Industrial AI Copilot ensures automation, proactivity, and operational decision-making, while a Conversational

Optimization of Production Processes and Production Progress Management for a Pharmaceutical Company

How to manage operational pauses without losing data? To avoid information loss and data fragmentation, it is essential to accurately track interruptions while maintaining the integrity of work orders even after a pause. In this article, we analyze how a pharmaceutical company overcame this challenge thanks to the Zerynth Platform, an Industrial IoT platform designed to optimize production processes even in the presence of interruptions. Operational context Production cycle interruptions are common during work shifts. In these situations, the operator stops the machine and later resumes the same work order at the same workstation. If these pauses are not