In the era of digital transformation, the food sector faces an unprecedented challenge: how to improve production efficiency without compromising quality and food safety?

It is in this context that Industrial IoT emerges as a catalyst for change, promising to revolutionize food production (and more). Through a synergistic fusion of advanced technology and culinary traditions, industrial efficiency in the food sector emerges as an essential path to ensure faster, more flexible, and safer production.

In this blog post, we will explore the reasons for this revolution, analyzing how Industrial IoT can transform the way we produce and consume food, redefining the boundaries of innovation in the Italian food industry landscape.

Do you own a food production company and want to digitize the entire process? Discover all our calls for proposals and incentives!

Production in the Italian Food Industry

What do the statistics of the food sector say? The industry is undergoing constant improvement: in the third quarter of 2023, there was a slight increase in economic performance, with a modest GDP rise of +0.1% compared to the previous quarter and the third quarter of 2022. However, this growth was accompanied by declines e in key sectors such as agriculture (-3.1%), industry (-1.3%), and services (+0.8%).

Statistics on food production in Italy indicate a growing domestic and foreign demand for high-quality products. However, the need to address energy challenges without compromising quality becomes essential to maintain competitiveness in the global market.

The food sector in Italy is one of the most crucial, and its success is the result of several elements that contribute to building a reputation for excellence nationally and internationally.

Let’s explore some of the main issues related to the food sector:

- High Energy Costs:

The Italian food industry often faces significant energy costs due to the considerable energy consumption required for production and preservation processes. These costs not only impact companies’ budgets but also contribute to worsened environmental sustainability.

- High Energy Consumption:

High energy consumption is often associated with production, refrigeration, and transportation activities in the food sector. Storage and distribution facilities require efficient energy management to reduce environmental impact and improve sustainability. - Maintaining Product Quality:

Preserving the quality of Italian food products is paramount. The European Union’s Geographical Indications system emphasizes the importance of maintaining the characteristics and distinctive quality of products by ensuring high standards for the final products, linked to their geographical location.

How IoT Can Address These Challenges:

In this context, one of the most effective and innovative solutions to address challenges in the food production sector involves the use of Industrial IoT technologies capable of integrating into the production environment to optimize resources, costs, and consumption.

- Energy Monitoring:

Implementing IoT solutions to monitor and optimize energy usage in production and preservation processes.

- Cold Chain Management:

Utilizing IoT devices to ensure efficient management of the cold chain, reducing waste and ensuring product freshness.

- Traceability and Quality:

Introducing IoT technologies for product traceability throughout the entire supply chain, ensuring food quality and safety. - Automation:

Implementing IoT-based automation systems to optimize production processes, reduce operational costs, and enhance overall efficiency.

The integration of IoT technologies in the Italian food industry marks a significant breakthrough. More and more Italian companies are choosing to implement such systems to reduce energy costs, improve sustainability, and simultaneously ensure the quality of the final product.

IoT offers a comprehensive approach to address challenges and transform them into growth opportunities for companies in the sector. Digitalization, through IoT, is the path toward more efficient, sustainable, and competitive food production in the global market.

Case Study – Food Production Company

An Italian food production company engaged in the collection, selection, and packaging of various delicacies, (such as mushrooms, truffles, berries, and vegetables) sought assistance from Zerynth. They aimed to streamline their production processes, automate the work of operators, and remotely monitor machinery.

Another requirement of the company was to access the tax benefits provided by the Industry 4.0 tax credit and interconnect its next-generation machinery, ensuring compliance with the 5+2 requirements.

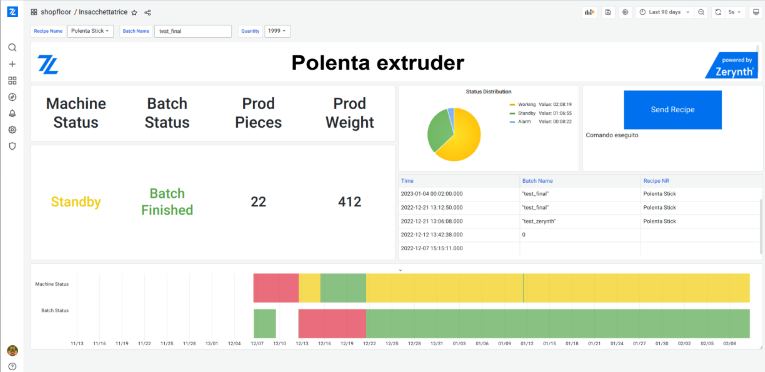

The solution chosen by Zerynth involved integrating the Zerynth Industrial IoT & AI Platform with the company’s modern machinery to create a connection between the machinery and the management system, enabling remote control and automation of on-machine activities.

Each piece of machinery was connected to the Zerynth Edge Device, allowing for data collection and extraction during operation. The data input process was automated, sending information to the Zerynth platform, which processes the data in real-time and displays it through dedicated dashboards.

The Zerynth platform offers a comprehensive overview of production machinery operations, highlighting consumption and process phases for each individual machine as well as aggregated data for the entire company.

Thanks to this implementation, the company can monitor production phases for each batch, gaining complete visibility into waste and the quality of final products. The extraction of data enables complete traceability of machinery operations, allowing remote control of processing phases, costs, machine hours, and pieces produced for overall production efficiency.

Learn more: visit our website and read the full case study!

Grants and Incentives for Smart and Sustainable 4.0 Solutions

Do you have a food production company and don’t know where to start the Industry 4.0 digitization process for enhanced efficiency? Zerynth is a partner of MADE Competence Center and Artes 4.0. By accessing their grants, supported by Zerynth, you can obtain a contribution of up to 100% of the costs incurred for the digital transformation of your company, up to a maximum of 400,000 euros.

Who can access these funds? Micro-enterprises, startups, SMEs, medium and large enterprises, as well as consortia formed by companies of various sizes that come together in a Temporary Association of Purpose (ATS).

Why choose Zerynth?

- Personalized Design and Development Services: With the support of our experts, you have the opportunity to create tailor-made projects, from ideation to validation, ready for implementation.

- Access to Innovation Financing: Your innovative ideas can benefit from funding covering up to 100% of the costs incurred, with a maximum of 400,000 euros. Micro-enterprises, startups, SMEs, and large enterprises, unite: there is room for everyone!

- Comprehensive Assistance in the Application Process: We guide you step by step during the submission of requests for funding related to technological innovation, ensuring that your proposals are robust and convincing.

Continue reading to discover all the details about the incentives available with Zerynth and the Competence Centers,or book a call with our IoT experts for a demo of the Zerynth Platform!

Share This Story, Choose Your Platform!

Follow Zerynth on

Latest Posts