In the landscape of the Italian manufacturing industry, optimizing production processes has become an indispensable priority. Emerging challenges call for innovative and reliable solutions to ensure a leap in quality in the production and connection of industrial machinery.

In this context, Zerynth positions itself as the ideal partner for System Integrators who aim to lead companies towards a complete and sustainable Industry 5.0 transformation.

From improving operational efficiency to swiftly addressing market challenges, Zerynth understands the specificities of the sector. In this blog post, we explore how our plug-and-play IoT & AI platform adapts to the distinct needs of each company, providing simple and intuitive solutions for optimizing production processes. Would you like to delve deeper? Meet us at one of our workshops dedicated to our partners. Discover upcoming Zerynth events and register now!

Challenges and Requirements to Improve Operational Efficiency in SMEs

In the era of Industry 4.0 (or dare we say, now Industry 5.0), streamlining operations, making production systems scalable and agile, is crucial for maintaining competitiveness in the market, eliminating waste, and reducing costs. In this context, Zerynth emerges as a leader in providing advanced Industrial IoT & AI solutions for the digitization and connection of industrial machinery.

But what are the most typical issues that Italian SMEs face in production optimization? For industries to optimize their production processes and enable a complete 5.0 transition, they need to:

- Obtain visibility into machinery operations

- Manage maintenance in a simple and proactive manner

- Reduce costs and energy consumption

- Interconnect and digitize both legacy and modern machinery

- Improve process efficiency and effectiveness

- Extract machinery data reliably

Monitoring Operating States and Alarms

One fundamental aspect to ensure operational continuity is the monitoring of operating states and alarm management. With Zerynth, companies can implement an advanced system that provides real-time visibility into the status of machinery, enabling a prompt response to alarms and the prevention of potential failures.

Data-Driven Maintenance Management

Preventive maintenance becomes more effective through the collection and analysis of machinery usage data. Zerynth enables companies to proactively plan maintenance interventions, reducing downtime to optimize production and resources.

Reduction of Energy Consumption

With the aim of promoting sustainability, Zerynth helps businesses monitor and reduce energy consumption. Thanks to intelligent control systems, companies can identify areas for optimization and implement targeted measures to reduce energy costs.

Digitization and Interconnection of Machinery

The Zerynth platform facilitates the digitization and interconnection of various types of machinery. This allows companies to manage the variety of devices in the production context uniformly, promoting greater flexibility and adaptability.

Process Efficiency and Effectiveness

Zerynth contributes to improving productivity through the integration of ERP and MES shop floor data. By minimizing downtime and failures, companies achieve greater operational efficiency and better production process management. These elements are crucial for meeting delivery times and overall improving the effectiveness of the production process.

Rapid and Reliable Collection of Process Data

By eliminating slow and unreliable data collection processes, Zerynth enables quick and automated analysis. This allows companies to estimate (and then optimize) production times and costs more accurately, facilitating a timely response to sudden problems.

Zerynth as a Partner for Production Efficiency

Zerynth stands out as a strategic partner for production efficiency, thanks to its established expertise in the IoT sector. Collaborating with Zerynth means gaining access to cutting-edge solutions that accelerate digital transformation, simultaneously enhancing the quality and productivity of your business.

Typically, within an Italian industrial shop floor, various types of systems collaborate for the overall operational efficiency of the industry, operating on different levels.

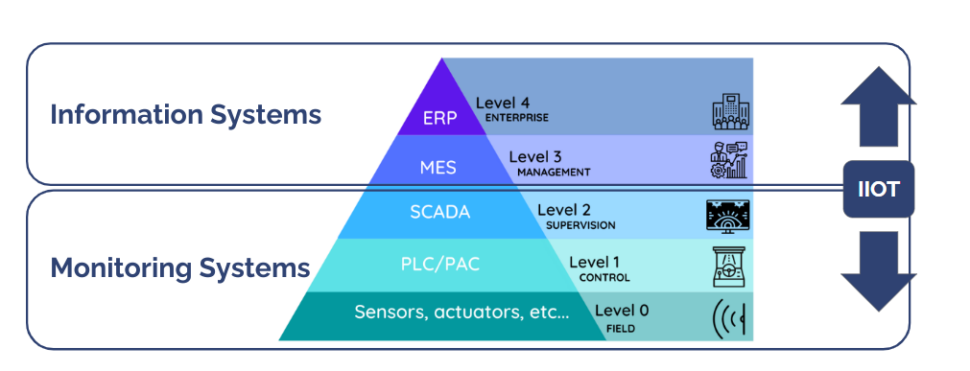

At the core (Fig 1), control systems certainly allow monitoring of production trends in the field and supervising correct operations through sensors, actuators, PLCs, or SCADA systems. On the other hand, informational systems such as ERPs or MES are indispensable for managing and optimizing production and orders for individual projects.

Where does Industrial IoT come in? It resides exactly in the middle, acting as a point of contact between these two types of systems, enabling a continuous flow of data between different platform types. This synergistic integration creates a cohesive ecosystem where data flows freely, enabling more efficient management and informed decision-making.

System integration is crucial to address the complex challenges of the industrial environment, offering a consolidated platform that integrates MES (Manufacturing Execution System), ERP (Enterprise Resource Planning), maintenance systems, and other key components already present in industries, enabling end customers to undergo a complete 5.0 transformation.

Centralizing data on a single platform eliminates information silos, improving communication and collaboration among different systems. This integrated approach not only enhances operational efficiency but also provides a holistic view of the factory, aiming to optimize overall company production processes.

Zerynth Hands-on Workshop for Our Partners

For several months now, we have been conducting our Zerynth Hands-on Workshops, free workshops proudly presented by Zerynth and designed exclusively for our partners. During these sessions, participants have the opportunity to develop practical skills in implementing the Zerynth Platform for the optimization of production processes.

The primary goal is to provide participants with best practices for creating and managing industrial IoT applications, allowing them to gain practical mastery of the solutions offered by the Zerynth platform.

The workshops aim to empower our partners to autonomously install the Zerynth Platform at their clients’ locations, promoting the exchange of experiences and expertise directly within client manufacturing companies. The ultimate objective is to accelerate the digital transformation process in the industrial context, enabling companies to fully leverage the potential of IoT to improve efficiency and drive innovation.

Last week, we were in Milan at the MADE Competence Center for the Smart Manufacturing Workshop: Zerynth x Odoo. There, we had the opportunity to engage with our partners and Odoo installers, explore the numerous connections, and the potential of the Zerynth x Odoo Connector and the Zerynth Platform as a whole.

Interested in meeting us and joining one of our workshops? Become part of our network and explore synergies between our entities! Discover all upcoming Zerynth training events.

Share This Story, Choose Your Platform!

Follow Zerynth on

Latest Posts