Challenges we address in Industrial Plant Maintenance

High impact of breakdowns and downtime

Reactive interventions are inefficient and take longer to execute.

Rising costs

Unplanned interventions increase marginal costs and extraordinary expenses.

Organizational difficulties

Optimally planning maintenance work is complex, adding inefficiency to daily operations.

Energy waste

Reduce your environmental impact by monitoring CO2 emissions, thus improving production efficiency.

What Benefits can you achieve?

Monitor, analyze and automate: our platform simplifies and enhances machine maintenance management.

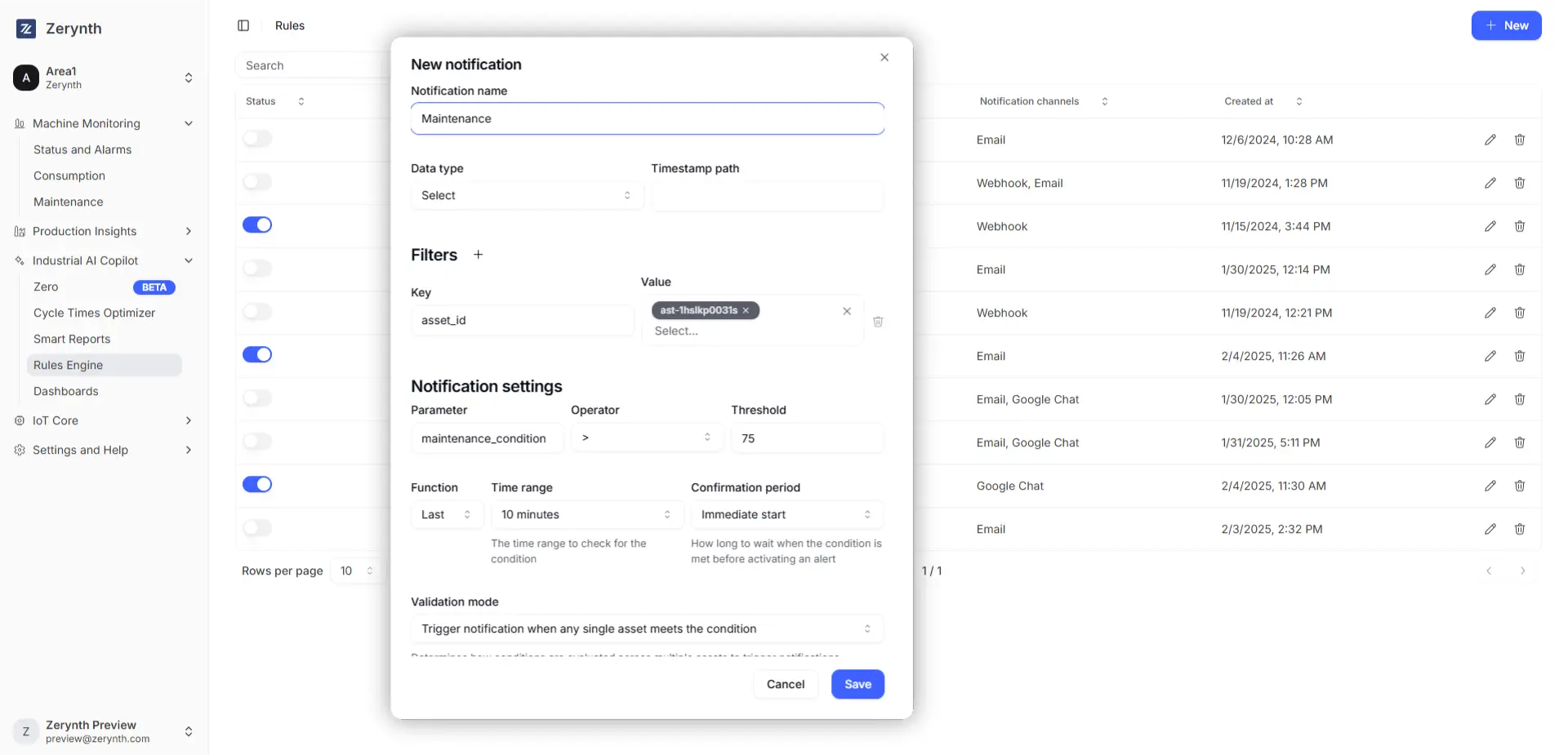

Set Automatic Rules

With Zerynth’s powerful Rules Engine, you can set critical thresholds and receive automatic alerts. After configuring maintenance schedules, shifts, and operators, you simply move on to automating the rules.

Based on the type of event in progress, you can set the alert of your choice. Harness the power of Zerynth’s AI to analyze your data, monitor machine conditions, and event start exploring predictive analysis!

Start reducing your maintenance costs now!

Supporting Your Digital Transformation

With Zerynth’s method, we offer advanced technology and a robust network of partners for a successful journey. We provide monitoring, interconnection, and machine visibility, enabling energy monitoring, enhanced process transparency, and integrated order tracking aligned with production.

Why choose Zerynth?

With Zerynth, you revolutionize maintenance management with a predictive and proactive solution that simplifies processes, reduces costs and improves operational efficiency. Our IoT and AI platform integrates seamlessly into your facilities, leveraging existing data to optimize processes without requiring invasive interventions or additional hardware.

What we offer:

Zerynth natively integrates with any BI, ERP, or MES

Easily connect enterprise third-party tools in a non-invasive way

The Zerynth Industrial IoT & AI Platform can natively interface with any industrial machinery in a simple and non-invasive manner, without interrupting machine operation, and offers quick integration with any BI, ERP, or MES already in your company.

Integration is also available with third-party tools through Rest Open API, Webhook, or certified connectors.