System integrators responsible for installing ERP/MES in companies often face the daunting challenge of gathering data from machinery, integrating systems and data, and delivering complete projects quickly and efficiently.

Our expert solution is designed to address these challenges by speeding up data collection from machinery (OT) and offering a seamless connection for industrial machinery.

What can you get?

What can you get?

What can you get?

What can you get?

Plug-and-play and automatic data

Extract data from machinery and send it to ERP/MES tools automatically, allowing to reduce errors and workload for offline operators.

Model fully compatible with SaaS, or on-prem

Digitizing any industrial machinery allows ERP and MES systems to expand their coverage in diverse and heterogeneous shop floor scenarios.

Any industrial machine connected in less than 3 hours, with our no-code configuration

Wi-Fi, Ethernet, and cellular connectivity options are available for a simple and scalable installation on both modern and legacy systems and plants.

Maximize your IT assets and reduce project delivery time

Leverage our solution to automatically extract data from machinery and seamlessly integrate it into your projects.

System integrators responsible for installing ERP/MES in companies often face the daunting challenge of gathering data from machinery, integrating systems and data, and delivering complete projects quickly and efficiently.

Our expert solution is designed to address these challenges by speeding up data collection from machinery (OT) and offering a seamless connection for industrial machinery.

What can you get?

What can you get?

Plug-and-play and automatic data

Extract data from machinery and send it to ERP/MES tools automatically, allowing to reduce errors and workload for offline operators.

Model fully compatible with SaaS, or on-prem

Digitizing any industrial machinery allows ERP and MES systems to expand their coverage in diverse and heterogeneous shop floor scenarios.

Any industrial machine connected in less than 3 hours, with our no-code configuration

Wi-Fi, Ethernet, and cellular connectivity options are available for a simple and scalable installation on both modern and legacy systems and plants.

Maximize your IT assets and reduce project delivery time

Leverage our solution to automatically extract data from machinery and seamlessly integrate it into your projects.

Address major industry challenges

What are the benefits of integrating the Zerynth Platform with ERP and MES systems?

- Data extraction and integration cycle reduction.

- Real-time production, process and asset monitoring.

- Top and shop floor interconnection.

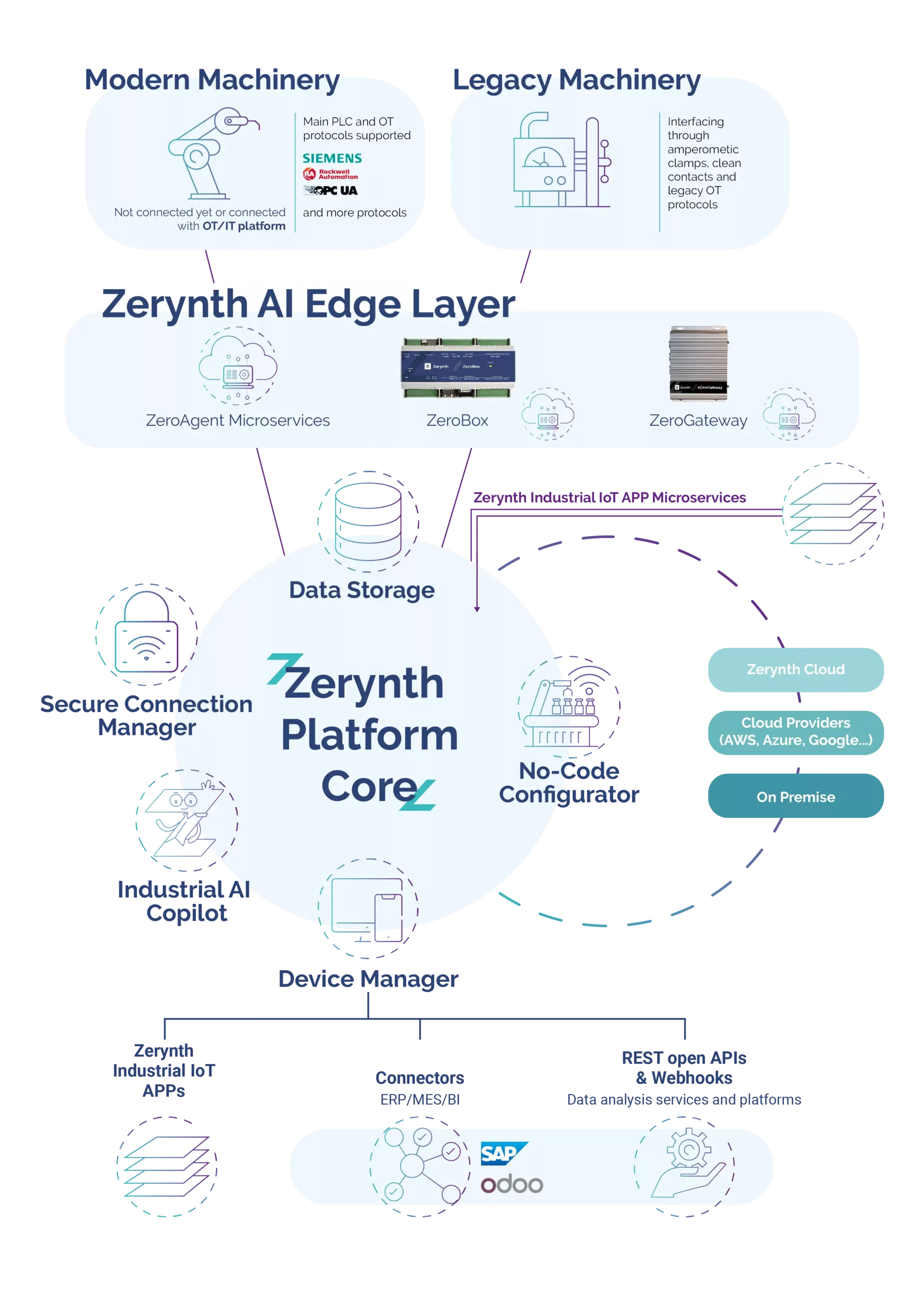

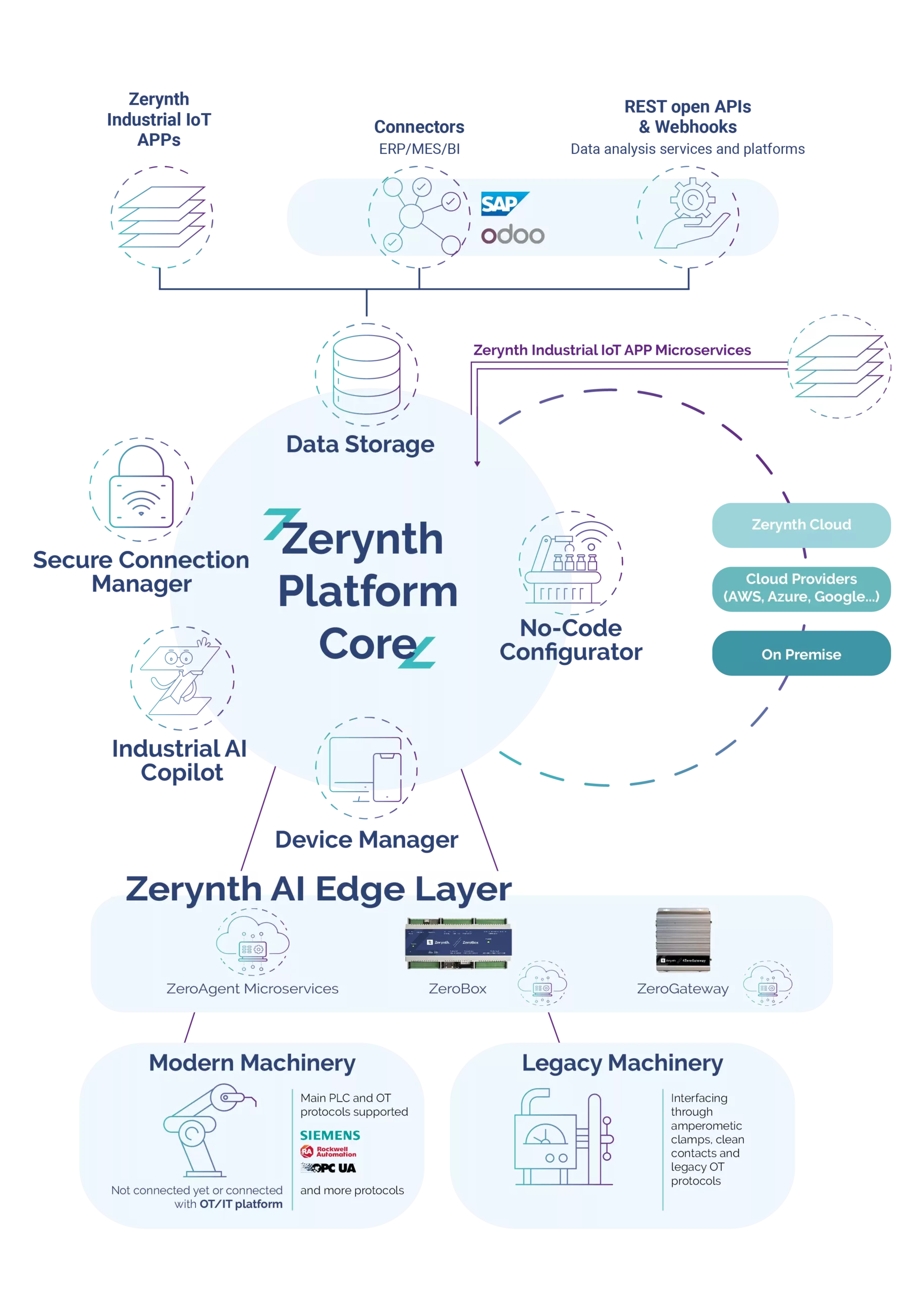

What types of industrial machines can be interfaced with the Zerynth Platform, and how is this integration achieved?

- The Zerynth Industrial IoT and AI Platform can interface with a wide range of industrial machines, including legacy and modern machinery, as well as auxiliary equipment and cabinets.

- The platform uses a modular architecture, which allows for easy integration with existing ERP and MES systems and other third-party tools.

- Integration with ERP and MES systems is typically achieved through REST APIs or webhooks, enabling seamless real-time data transfer between systems.

Address major industry challenges

What are the benefits of integrating the Zerynth Platform with ERP and MES systems?

- Data extraction and integration cycle reduction.

- Real-time production, process and asset monitoring.

- Top and shop floor interconnection.

What types of industrial machines can be interfaced with the Zerynth Platform, and how is this integration achieved?

- The Zerynth Industrial IoT and AI Platform can interface with a wide range of industrial machines, including legacy and modern machinery, as well as auxiliary equipment and cabinets.

- The platform uses a modular architecture, which allows for easy integration with existing ERP and MES systems and other third-party tools.

- Integration with ERP and MES systems is typically achieved through REST APIs or webhooks, enabling seamless real-time data transfer between systems.

Address major industry challenges

What are the benefits of integrating the Zerynth Platform with ERP and MES systems?

- Data extraction and integration cycle reduction.

- Real-time production, process and asset monitoring.

- Top and shop floor interconnection.

What types of industrial machines can be interfaced with the Zerynth Platform, and how is this integration achieved?

- The Zerynth Industrial IoT and AI Platform can interface with a wide range of industrial machines, including legacy and modern machinery, as well as auxiliary equipment and cabinets.

- The platform uses a modular architecture, which allows for easy integration with existing ERP and MES systems and other third-party tools.

- Integration with ERP and MES systems is typically achieved through REST APIs or webhooks, enabling seamless real-time data transfer between systems.

The power of IoT & AI technology

Zerynth Industrial IoT & AI Platform Architecture

The power of IoT & AI technology

Zerynth Industrial IoT & AI Platform Architecture

Resources

Resources

Resources

Resources

Resources