What Are the Benefits?

What Are the Benefits?

What Are the Benefits?

What Are the Benefits?

Visibility into KPIs from Connected Products Installed Anywhere in the World

Receive precise real-time data on location, performance and other metrics of your product to improve performance t and take informed business decisions based on the insights.

Optimize maintenance and ensure uptime

Manage maintenance schedules, prevent downtimes and reduce on-site visits.

Turn your product into a service and diversify your revenue stream

Deliver ongoing value and benefits to customers through IoT technology, including real-time monitoring of machinery, predictive maintenance, and customized recommendations.

Reduce service costs

IoT-enabled remote monitoring lowers costs and reduces downtime by allowing businesses to monitor equipment from afar, minimizing on-site visits and expenses.

What are the Benefits?

What are the Benefits?

Visibility into KPIs from Connected Products Installed Anywhere in the World

Receive precise real-time data on location, performance and other metrics of your product to improve performance t and take informed business decisions based on the insights.

Optimize maintenance and ensure uptime

Manage maintenance schedules, prevent downtimes and reduce on-site visits.

Turn your product into a service and diversify your revenue stream

Deliver ongoing value and benefits to customers through IoT technology, including real-time monitoring of machinery, predictive maintenance, and customized recommendations.

Reduce service costs

IoT-enabled remote monitoring lowers costs and reduces downtime by allowing businesses to monitor equipment from afar, minimizing on-site visits and expenses.

We Support Companies at Every Stage of Digital Transformation

How Can I simplify the Maintenance of connected products?

- By integrating our cutting-edge IoT and AI solutions, machine manufacturers and installers can offer their customers simple and low-effort maintenance.

- Utilize self-monitoring sensors and alarms to implement proactive maintenance.

- Solve problems remotely and enhance your diagnostic capabilities.

- Receive automatic software updates for better performance and increased security.

How Can I Enhance my Service Features?

- Remote machinery monitoring enables quicker response times to issues.

- With Zerynth, you can reduce the need for on-site service visits.

- Optimize preventive maintenance schedules.

Why is Zerynth the Right Platform for OEMs?

- We provide a user app for your customers and a backend app for your after-sales or R&D teams.

- With Zerynth, you won’t have to worry about IT, customization, or integration with management systems.

- The Zerynth OEM Backend App allows you to collect, store, and analyze data for after-sales and data-driven R&D initiatives.

We Support Companies at Every Stage of Digital Transformation

How Can I simplify the Maintenance of connected products?

- By integrating our cutting-edge IoT and AI solutions, machine manufacturers and installers can offer their customers simple and low-effort maintenance.

- Utilize self-monitoring sensors and alarms to implement proactive maintenance.

- Solve problems remotely and enhance your diagnostic capabilities.

- Receive automatic software updates for better performance and increased security.

How Can I Enhance my Service Features?

- Remote machinery monitoring enables quicker response times to issues.

- With Zerynth, you can reduce the need for on-site service visits.

- Optimize preventive maintenance schedules.

Why is Zerynth the Right Platform for OEMs?

- We provide a user app for your customers and a backend app for your after-sales or R&D teams.

- With Zerynth, you won’t have to worry about IT, customization, or integration with management systems.

- The Zerynth OEM Backend App allows you to collect, store, and analyze data for after-sales and data-driven R&D initiatives.

We Support Companies at Every Stage of Digital Transformation

How Can I simplify the Maintenance of connected products?

- By integrating our cutting-edge IoT and AI solutions, machine manufacturers and installers can offer their customers simple and low-effort maintenance.

- Utilize self-monitoring sensors and alarms to implement proactive maintenance.

- Solve problems remotely and enhance your diagnostic capabilities.

- Receive automatic software updates for better performance and increased security.

How Can I Enhance my Service Features?

- Remote machinery monitoring enables quicker response times to issues.

- With Zerynth, you can reduce the need for on-site service visits.

- Optimize preventive maintenance schedules.

Why is Zerynth the Right Platform for OEMs?

- We provide a user app for your customers and a backend app for your after-sales or R&D teams.

- With Zerynth, you won’t have to worry about IT, customization, or integration with management systems.

- The Zerynth OEM Backend App allows you to collect, store, and analyze data for after-sales and data-driven R&D initiatives.

Seamless integration with any BI, ERP or MES

Seamless integration with any BI, ERP or MES

Seamless integration with any BI, ERP or MES

Seamless integration with any BI, ERP or MES

Easily connect enterprise third-party tools in a non-invasive way

The Zerynth Industrial IoT and AI Platform can interface with Industrial machines easily in a non-invasive way, without interrupting the machinery, offering fast integration with any BI, ERP or MES already present in your company.

The integration is also available with third-party tools through Rest Open APIs or Webhooks.

The power of IoT & AI technology

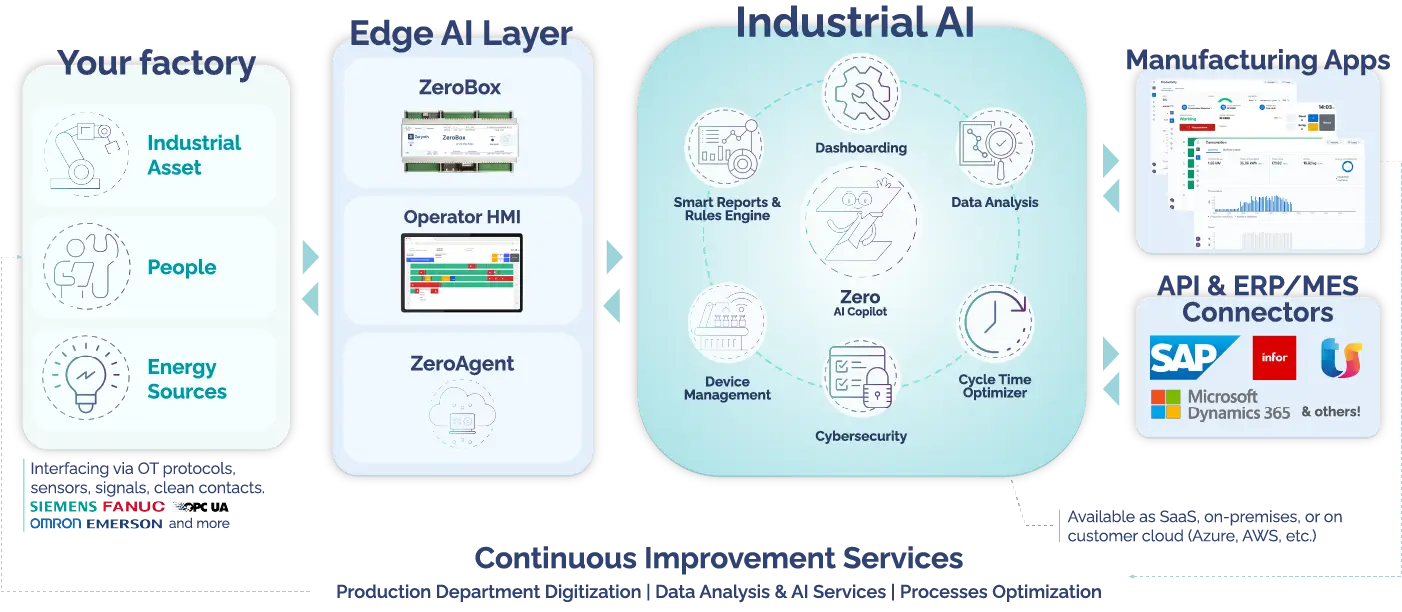

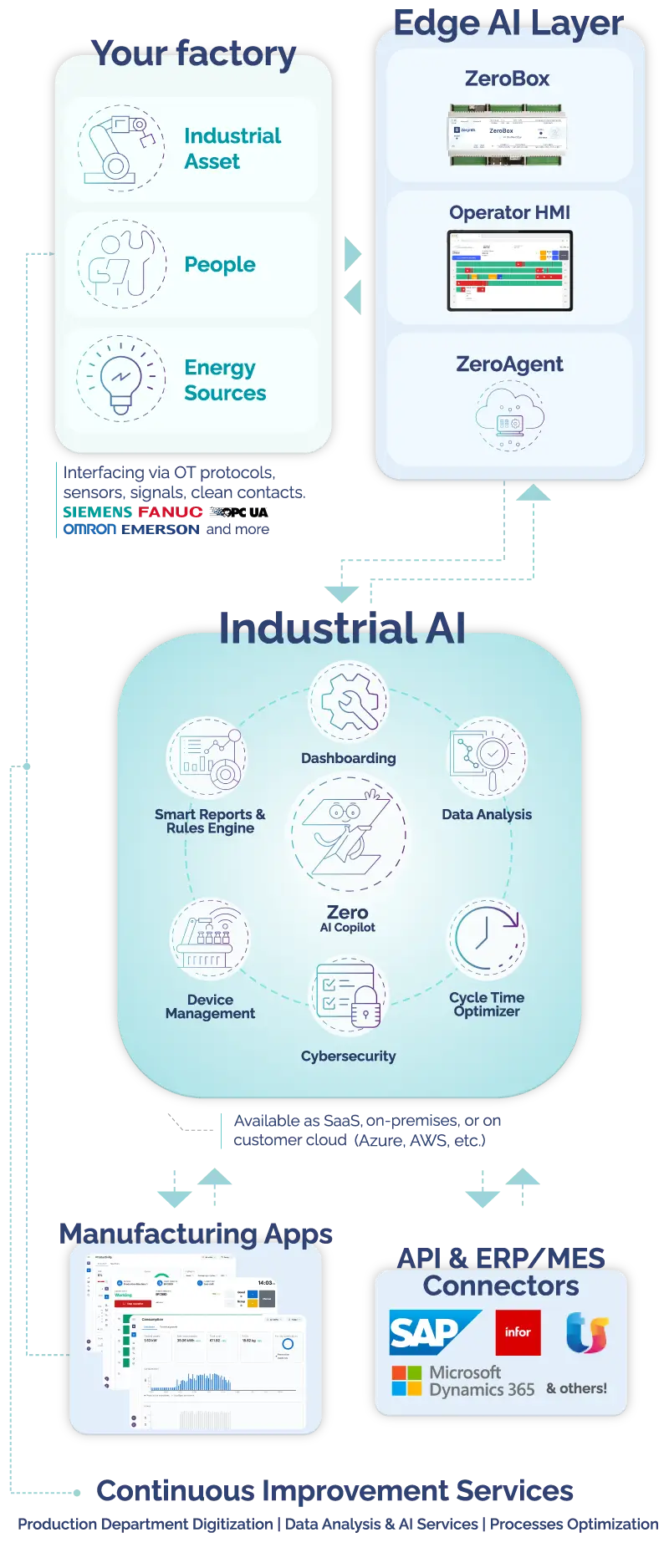

Zerynth Industrial IoT & AI Platform Architecture

The power of IoT & AI technology

Zerynth Industrial IoT & AI Platform Architecture

Resources

Resources

Resources

Resources

Resources