We look forward to seeing you at Viva Technology 2025!

Meet Zerynth at Viva Technology 2025

Paris Expo Porte de Versailles

June 11-14, 2025

Hall 1, Booth C15-048

Fast-Track your factory’s digital transformation.

Visit our Booth!

📅 June 11-14

📍 Hall 1 – Booth C15-048

Zerynth is exhibiting at Viva Technology 2025, Europe’s leading tech event. Visit us to explore how we help manufacturers digitize production assets, optimize energy consumption, and fain full visibility over industrial process, without replacing existing machines.

Our Industrial AI Platform connects legacy equipment in few hours. Scalable, secure and tailored to your operations.

Join us on stage!

📅 June 12

🕐 12:15 – 12:45 CET

📍 Hall 1 – Stage C15

During the session “Industry 4.0 & Robotics, Cyber Security & Data Protection”, our CEO Gabriele Montelisciani will present how Zerynth enables smart manufacturing with measurable impact. In 3 minutes, you’ll get a clear view of:

- Who we are and how we support industrial SMEs

- The real-world results of plug-and-play IoT & AI

- Why data-driven decision making starts at the machine level

Let’s Talk!

If you’re attending Viva Technology and looking for actionable ways to digitalize your factory floor, come see us.

Want to skip the line? Book a meeting in advance.

Discover the Zerynth’s Apps

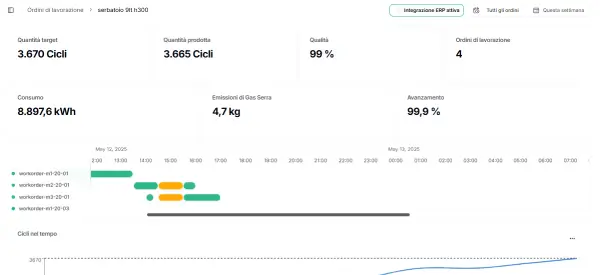

From real-time monitoring of machinery and factory energy consumption to the calculation of advanced production KPIs, Zerynth’s IoT Apps act as powerful microservices that transform raw data into valuable KPIs—accessible via API or through intuitive graphical interfaces.

Machine Monitoring

To monitor all machines and assets, check their status in real time, reduce energy costs, minimize downtime, and manage maintenance.

Production Insights

To make production processes more efficient, gain intelligent insights, optimize productivity (OEE), accurately monitor processing times, and estimate production costs.