Take Full Control of Your Work Orders

Work Orders Management leverages AI to connect the shop floor with management systems, providing a single, up-to-date view of order status, production progress, and sustainability KPIs. Designed for immediate value without lengthy integration projects, it can be scaled and extended based on your priorities.

Shop Floor and Management System Integration

Overcome poor interconnection between machines and ERP/MES with intelligent edge, ensuring continuity and low latency even with unstable cloud connections.

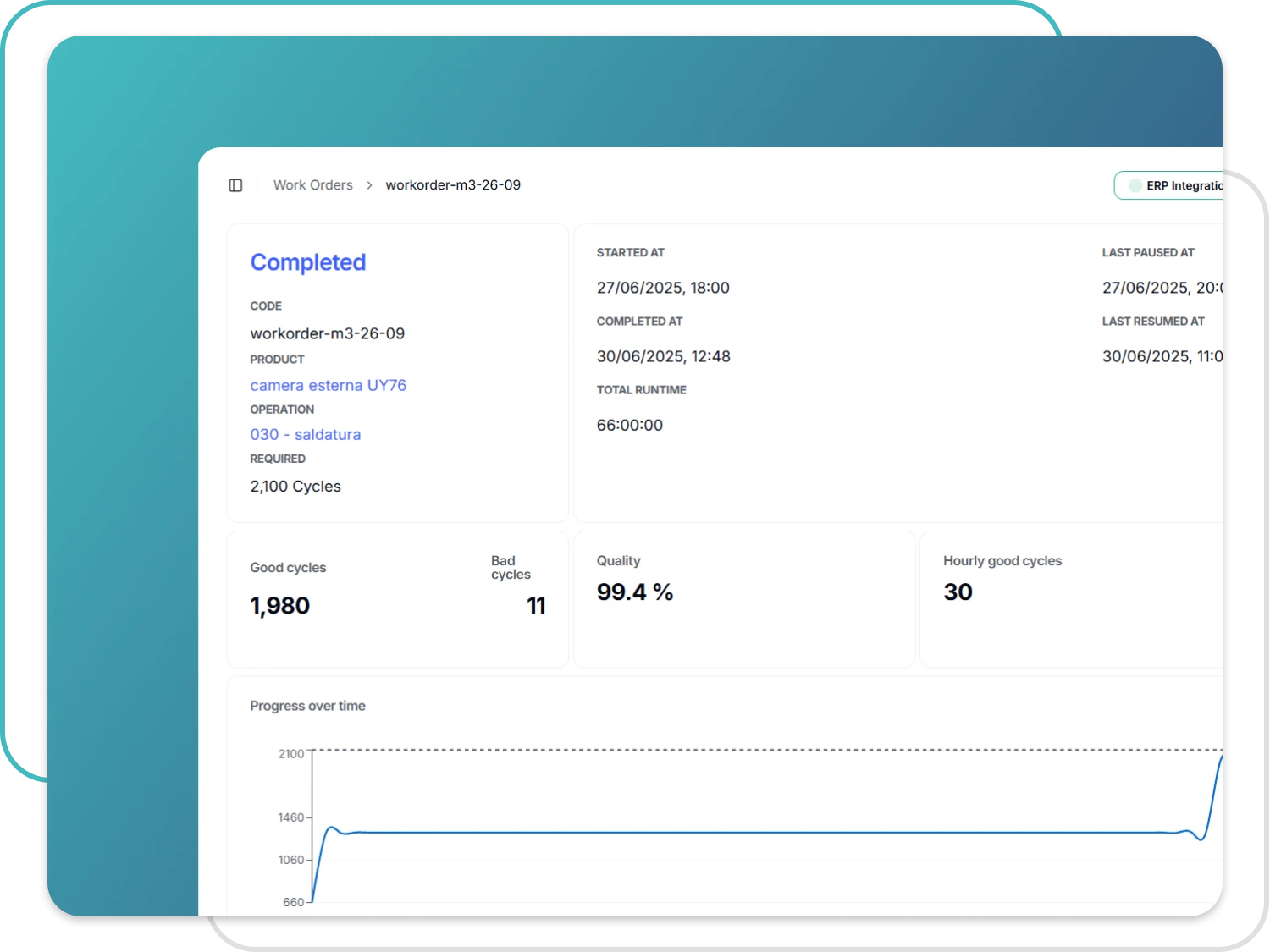

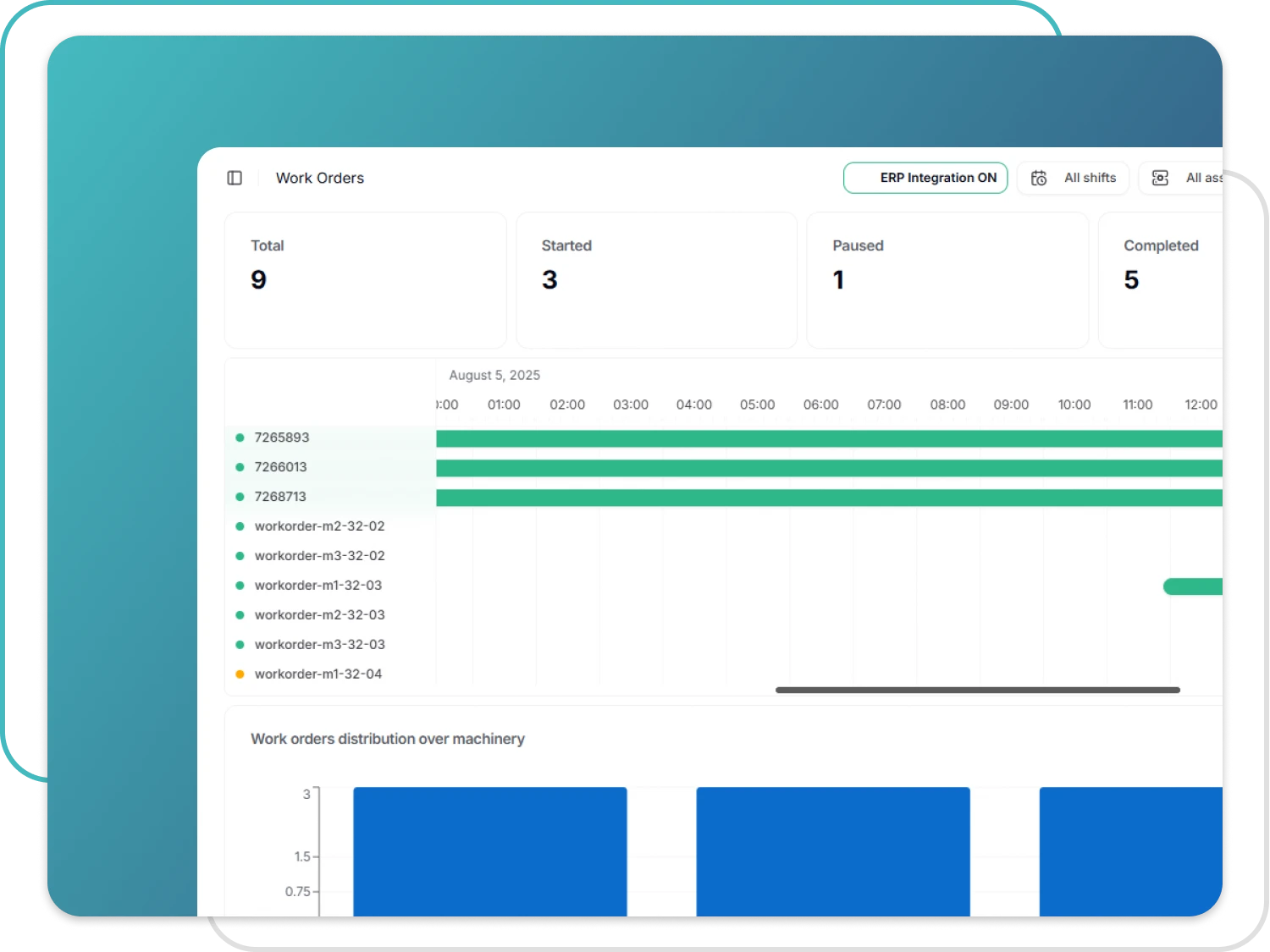

Order and Productivity Visibility

Gain a reliable, real-time view of production progress, consumptions and KPIs, eliminating incomplete or duplicate information.

Immediate Data-Driven Decisions

Access consistent, centralized data to make quick, informed decisions and reduce downtime risks.

Key Features

See how Work Orders Management simplifies order handling and enables real-time, data-driven decision-making.

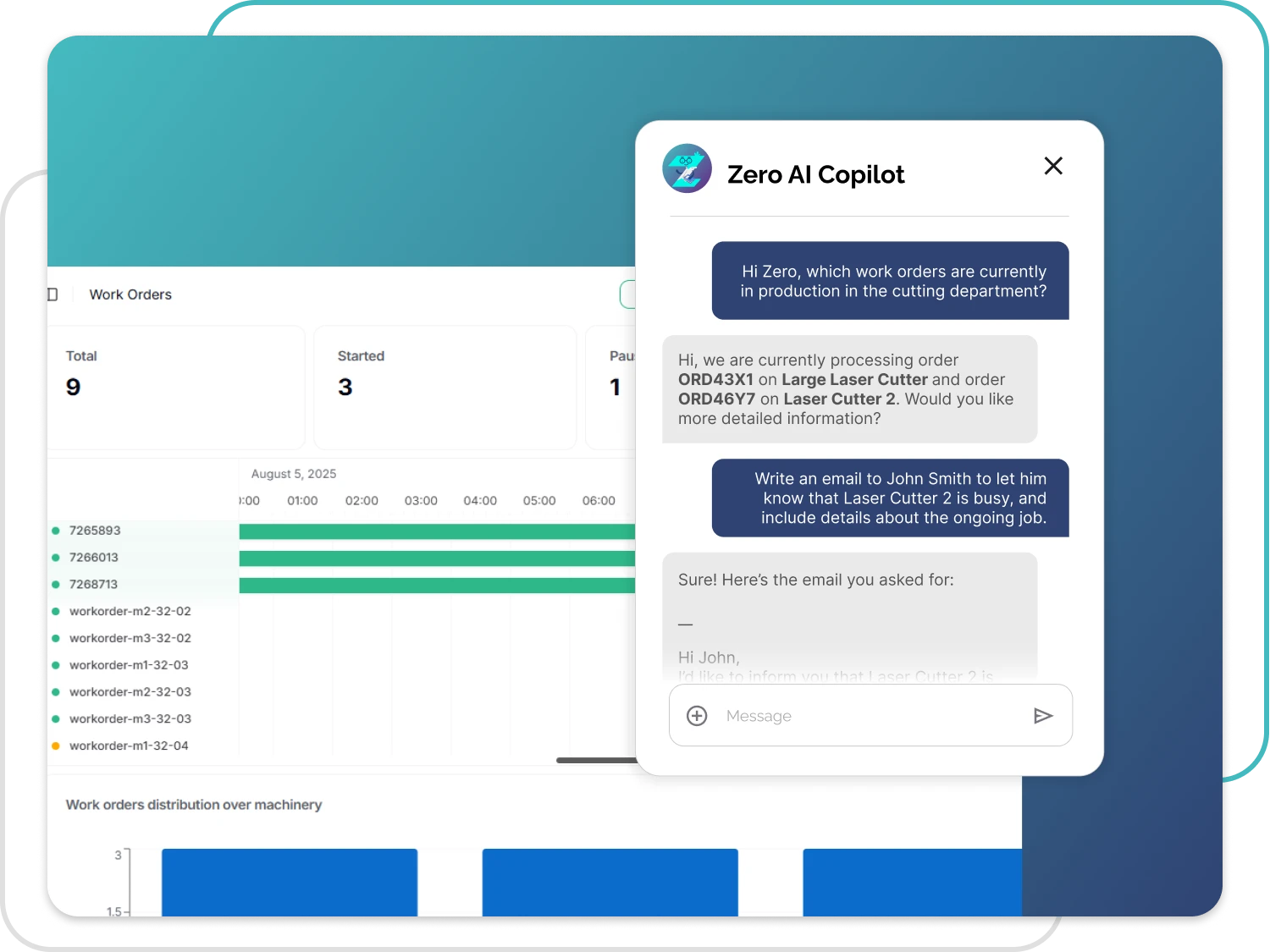

Digital Integration with AI Copilot

Work Orders Management eliminates spreadsheets and disconnected systems by uniting production and management data into one platform. With an integrated view, you reduce inconsistencies and duplicates while gaining always-available metrics to guide decisions.

This is where the AI Copilot becomes a true decision-making ally—mapping processes, integrating systems (MES, ERP, etc.), and supporting advanced work order management so you can act quickly and effectively.

Native Integration with Any BI, ERP, or MES

Seamlessly integrate with third-party management systems without disrupting operations

The Zerynth Industrial IoT & AI Platform connects to any industrial machine easily and non-invasively—without interrupting its operation—and integrates quickly with any existing ERP, MES, or BI system.

Third-party integrations are also available via REST Open API or WebHook.