Artificial intelligence in the factory is revolutionizing how people and technology interact. It’s no longer just about automation, but about collaboration with intelligent systems that can analyze, predict, and suggest actions.

Many companies are exploring AI, but the real challenge is moving from intention to implementation. Zerynth helps manufacturers turn data into a daily strategic resource.

We embrace a collaborative approach: AI that enhances human work, improving decision-making, safety, and productivity. This collaborative artificial intelligence model differs from traditional automation because it keeps human experience and judgment at the center.

The New Role of Senior Operators

Senior operators — professionals responsible for process supervision and line coordination — are key players in digital transformation. In the era of artificial intelligence in the factory, they work in connected environments where sensors and IoT platforms generate real-time data. AI simplifies complexity: it highlights only relevant anomalies, streamlines monitoring, and allows faster reactions.

Operators become knowledge workers of production, capable of interpreting data to improve processes. This new collaboration between humans and machines requires accessible tools and continuous training to develop data literacy. Artificial intelligence for production monitoring enables teams to focus on what truly matters: quality, efficiency, and consistency.

Technicians at the Heart of Transformation

Technical professionals — such as production, maintenance, IT, and OT managers — are the operational core of the smart factory. They manage machines, infrastructure, and digital systems, turning data into action. Artificial intelligence in manufacturing expands their analytical and operational capabilities: they interpret complex information, coordinate teams, and drive continuous improvement.

Production and Operations Managers

These professionals lead production lines and oversee efficiency, planning, and quality control. Their main challenge is to maintain productivity while minimizing waste. Artificial intelligence for production monitoring helps optimize OEE and anticipate bottlenecks, making planning more effective. With advanced analytics and AI-based tools, managers can visualize KPIs, orders, and line performance in a single view, taking corrective action in real time.

Maintenance and OT Managers

Maintenance technicians and OT Managers stand at the intersection of machines and data. Artificial intelligence applied to machine maintenance is transforming asset management: IoT sensors help predict faults, schedule interventions, and optimize equipment uptime. These professionals become reliability analysts and guardians of production continuity.

As described in our previous article “How Zero AI Copilot Helps Solve Emerging Challenges in Smart Manufacturing, tools like Zero, Zerynth’s industrial AI Copilot provide a complete overview of asset status and consumption, helping identify anomalies and priorities for action. Predictive maintenance thus becomes a strategic function ensuring reliability, safety, and performance.

IT and Energy Managers

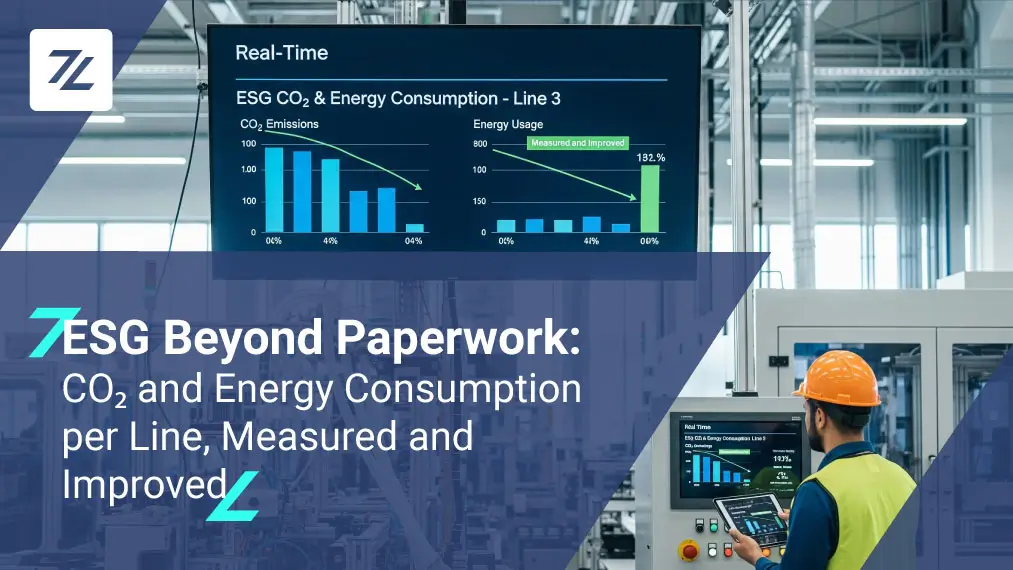

These roles bridge technology and operations. In the smart factory, IT/OT convergence is essential for ensuring security, connectivity, and sustainability. AI in manufacturing creates a unified ecosystem connecting digital infrastructure, machinery, and energy systems. AI-driven solutions analyze energy consumption and suggest strategies to reduce waste and improve sustainability. Energy and IT managers can thus monitor efficiency and manage production data securely and cohesively.

Managers and Strategic Governance of AI

Artificial intelligence in the factory is not just an operational technology, but a strategic lever for governance. Successful managers build a data-driven culture by investing in skills, processes, and communication. Change management is crucial to overcoming cultural barriers and transforming AI into a true competitive advantage.

Zerynth supports decision-makers in building this culture, providing tools that turn data into clear, actionable insights. In this way, technology becomes an integral part of business strategy, guiding investments, priorities, and performance.

Where to Start

Many companies hesitate to introduce artificial intelligence in the factory due to perceived complexity or cost. In reality, the journey begins with small, practical pilot projects.

Analyzing downtime, introducing predictive alerts, and monitoring energy consumption are excellent ways to start seeing results quickly.

With Zerynth’s approach, manufacturers can evolve step by step, moving from pilot projects to large-scale deployment. Each step builds competence, reduces inefficiencies, and strengthens trust in data as a driver of growth.

Share This Story, Choose Your Platform!

Follow Zerynth on

Latest Posts