In today’s era of continuous industrial evolution, the complete digitization of production processes allows the connection of machinery and integration with advanced systems already in place on the shop floor.

The new incentives provided by the government, along with calls for proposals, and digitization funds, are increasingly encouraging Italian businesses to embark on a true path of digitization with an Industry 4.0 perspective, aiming to automate all resources involved in production processes.

In this context, the use of specialized technologies for the digitization of industrial machinery, both legacy and modern, within the IT infrastructure and the ecosystem of processes managed by the company’s ERP, becomes crucial.

In anticipation of the first exclusive training for Odoo Partners on February 16 at the Made Competence Center, this article will explore how to leverage the capabilities of the Zerynth IoT platform combined with the Odoo connector to build an advanced solution for integrating IoT technologies in the digitization of machinery and industrial processes.

Why integrate your SME systems

The integration of systems plays a crucial role in the digital transformation of the industry, particularly in the context of industrial production. Italian manufacturing companies often use diverse systems (when present) to track production, manage maintenance, or optimize the supply chain.

Due to the lack of investments in appropriate digital tools for operators and managers in the sector, ensuring complete integration of all existing systems becomes essential to enable a smoother and more efficient flow of information.

It’s not just the optimization of operational processes that matters, the overall improvement of visibility and control over the entire production chain is also crucial. This enables real-time understanding and informed decision-making based on data across multiple fronts—from production management to warehouse and supply chain management.

By gaining visibility into production and integrating this information with other systems, not only is operational efficiency maximized, but it also opens the door to continuous optimization opportunities for more complex data analysis and AI models.

The Zerynth Connector for Odoo moves precisely in this direction, serving as a liaison between the various modules of Odoo, particularly in industries that already use it as a management system but have yet to fully integrate production.

Bidirectional communication to enable Industry 4.0

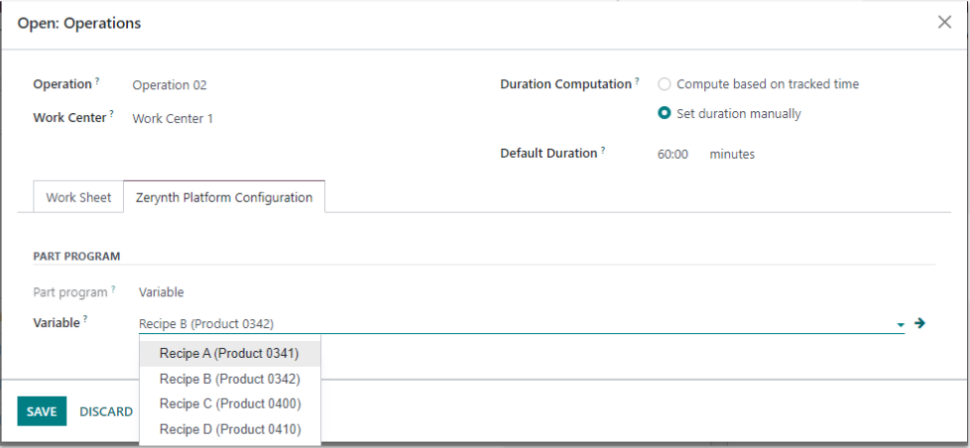

Modern ‘4.0 Ready’ machines allow for the remote loading of instructions (Part Program) onto the PLC, which is necessary to initiate the process. In many cases, these instructions are files generated by CAD/CAM software to define the processing path. In other cases, they consist of a series of variable machine settings (recipes) saved with a unique code for each operation or product.

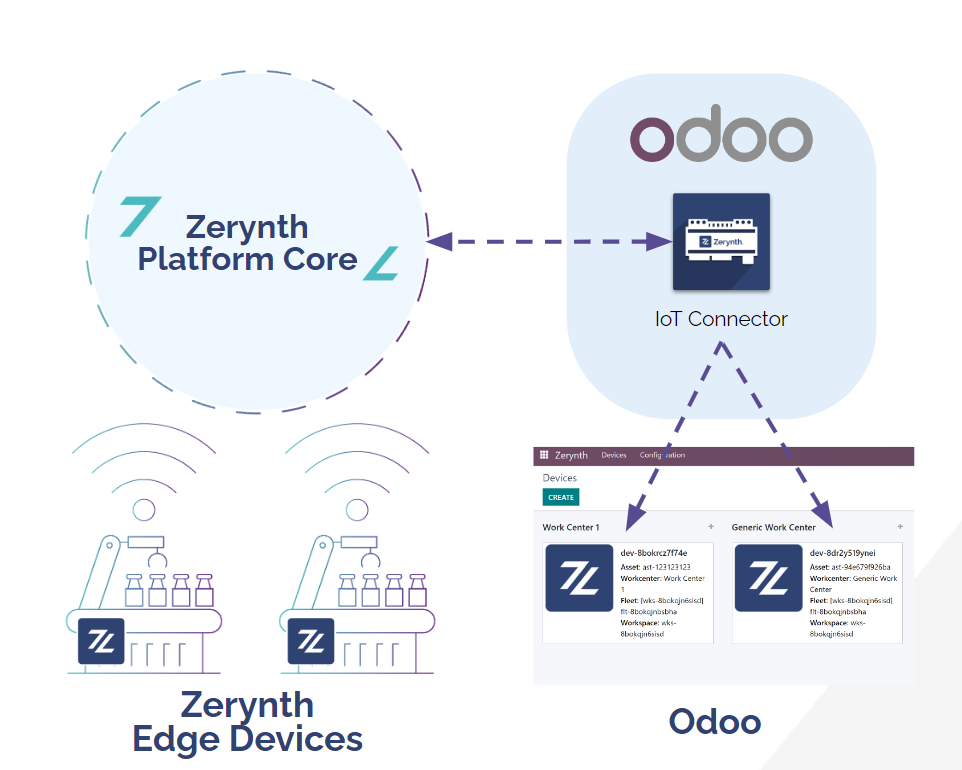

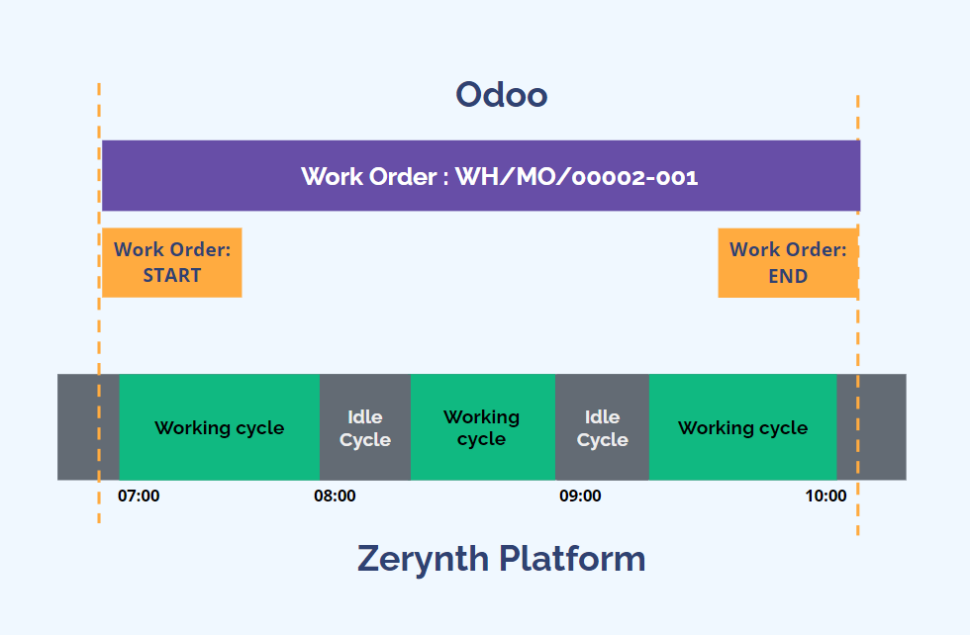

Machine control is enabled through bidirectional communication between Zerynth and Odoo. Specifically, the machine exchanges data with the Zerynth platform through the Zerynth Edge Device installed on the machine itself.

The Connector enables a process of automated data exchange between the two platforms. Once the two accounts are connected, within the Zerynth app inside Odoo, digital twins of IoT devices are created, and these can be linked to the Work Centers available on Odoo.

Zerynth Connector for Odoo: IoT and ERP Integration for Complete 4.0 Transformation

The Zerynth Connector for Odoo offers advanced and automated integration between IoT solutions and the ERP system for production management. Its capability to handle work cycles, work orders, and the configuration of Industry 4.0 machinery makes it an indispensable ally for companies aiming for a complete transformation towards Industry 4.0. The flexibility in loading part programs and efficient data management contribute to optimizing production processes and increasing the value of connected industrial products.

Here are some of the key features to consider:

- Work Center Configuration: Proper configuration of the work center is crucial for the connector’s correct operation, and various additional functions can be enabled, including the automatic closure of work orders.

- Control of Industry 4.0 Machinery: Bidirectional communication between machinery and the Zerynth Edge Device enables the ability to control the machinery directly from Odoo, using four possible modes for loading the part program.

- Flexible Production Management: Production can be configured for both repetitive items and items produced to specification, defining the insertion of the part program either based on the bill of materials or for the individual work order.

Subscribe to our newsletter to discover in more detail all the features of the Zerynth Connector for Odoo and stay updated on upcoming releases!

Zerynth Training for Odoo Italy comes to Milan

On Friday, February 16th, we will be in Milan at the MADE Competence Center, where our first exclusive training for Odoo Partners will take place.

At the event, there will be a brief introduction from MADE and Odoo Italy, followed by an overview of the current state of digitization in Italian SMEs. The session will also cover the features of the Zerynth connector and practical training on its usage.

The Zerynth Connector for Odoo represents a key element for the complete transition to Industry 4.0, enabling advanced control and optimized management of industrial processes. However, to maximize the benefits of this integration, it is essential not only to fully understand the capabilities of the connector but also to establish significant synergies with Odoo partners.

Building strong relationships with business entities allows the creation of a collaborative ecosystem, crucial for addressing challenges and seizing opportunities during the transition.

Register for the event and discover how to maximize the benefits of integration with Odoo and automate production processes with Zerynth!